The Future Of 3D Printing - Introduction to Water-Cooled Hotends

Introduction

In this article, we're going to take a look at the future of 3D printing, as we dive deep into how water-cooled hotends work and the options that are currently available. If you're not familiar with them yet, don't worry: it's pretty easy to get started. First, let’s take a little look at what a hotend is and how it works.

What is a 3D printing hotend and how does it work?

You may be wondering, "What is a hotend?"

A hotend is the part of a 3D printer that heats up to melt the plastic filament. The filament is pushed into the hotend by the extruder, which then flows through and out of the nozzle. The heated nozzle controls the width of the melted filament that is pushed out and onto your print surface to create an object.

Typically, the hotend will have 2 devices attached to it that are used to heat it. First, there is a heater cartridge that provides the heat to melt the filament and is attached to your printer's control board and controlled by its firmware. Second, a thermistor is used to measure the temp of the hotend. This thermistor is also attached to your printer's control board and it constantly measures the temperature and will turn the heater cartridge on and off to keep the hotend at the desired temp.

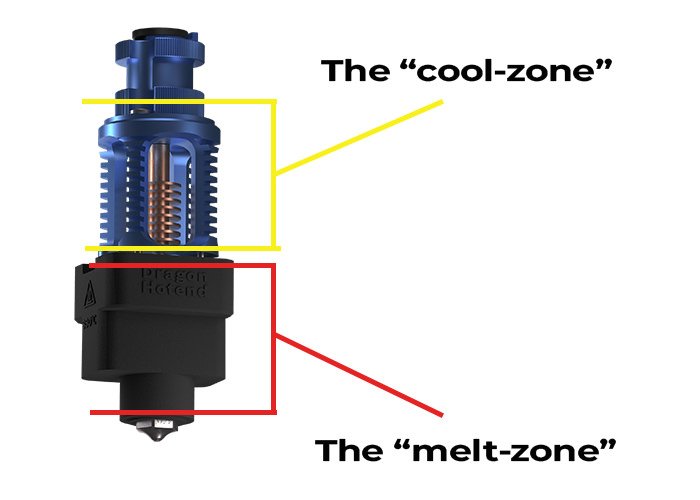

Hotends are most commonly made out of a combination of metals, these different materials have different purposes which help control the concentration of heat in one area, most commonly called the “melt-zone”. This “melt-zone” is located towards the bottom at the nozzle. The top of the hotend is considered the “cool-zone”. This is where the filament must remain a solid to be able to be pushed by the extruder before it hits the “melt-zone” and becomes a liquid.

Since melted plastic is extremely viscous, the hotend needs to reach high temperatures in order to operate effectively. Most of the basic, entry-level hotends will have a maximum heating temperature of 280-300°C. This temperature is a result of the materials used in the hotend and the type of thermistor that is installed. Most standard thermistors are only able to read temps up to 300°C which is fine for the majority of consumer 3D printing filaments that one might be using.

The hotend needs heat to melt the plastic but it also needs to be cooled to control the effectiveness of the melt-zone. To accomplish this, the majority of hotends available have a fan that is constantly blowing on the heatsink section of the hotend. This prevents “heat-creep” or the expansion of the “melt-zone” up into the “cool-zone”. If there wasn’t a fan to keep this section cool, the heat will eventually cause the filament to melt and contract/expand which can cause clogging and will most likely ruin whatever it is you’re printing.

Most hotends won’t have a problem with clogging if you’re printing at low speeds and without the use of an enclosure. The hotend fan will do a sufficient job to keep things cool.

So why would anyone want to water-cool their hotend?

For most 3D printer users, their stock hotend fan will be more than adequate to meet their needs. However, there are a few situations where they might not perform as well.

First, one of the primary problems with hotends is that they can get too hot when printing continuously for long periods of time. This causes a few issues but the biggest one is clogging. The fan won’t be able to keep the top of the hotend cool enough which will allow the filament to soften towards the extruder.

Second, if using a printer that has an enclosure, the internal temperature of that enclosure will be quite high due to being passively heated by the heated bed. Since the air inside is warmer, the fan on the hotend will be pushing warm air which will have very little effectiveness for cooling.

Third, if you are wanting to print at high speeds, you will need to increase the temp on your hotend. The faster the filament is pushed through, the hotter the hotend must be to melt the filament. This can result in your fan not being able to limit the spread of heat which can result in “heat-creep”.

Fourth, because it’s cool.

How does water-cooling work?

Instead of a fan blowing air over the hotend heatsink, cooled water is circulated through it which absorbs the heat from the metal. The now warmer water travels back out of the hotend, is passed through a radiator where it is cooled, and then circulated back to the hotend in a loop. This is how the hotend stays cool.

What are all the components of a water-cooled hotend?

A water-cooled hotend will have a few parts: a water pump, a reservoir, a radiator, a fan, tubing, and a special heatsink on the hotend.

The pump circulates the water through the system in a loop.

The reservoir contains enough liquid to keep things cool. A bigger reservoir can result in lower temps as there will be more water to absorb heat and will be easier to cool.

The radiator is responsible for cooling the water. It usually consists of a winding path of tubes that the water flows through. These tubes increase the surface area to be cooled. A fan on top of the radiator pushes cool air over these tubes to remove the heat in the water that was picked up by the hotend.

The tubing is what connects all these different parts together.

Lastly, the heatsink on the hotend. Water is pushed through and absorbs the heat that is rising up from the “melt-zone”.

What water-cooled hotends are currently available?

Water-cooled hotends have been around for a while, mostly in high-end industrial machines, and have never really been popular in the consumer mainstream. Most of the main 3D printing component manufacturers have a water-cooled option but since these components require a whole mess of parts that aren’t included, their use is usually limited to the 3D printing enthusiast rather than the average home user. A lot of research is involved in picking out these parts to make sure everything is compatible. After that is done, you need to figure out how to mount, wire, and run your tubing. Again, this is usually outside the scope of the average users skills.

With all of that out of the way, let’s take a look at what water-cooled options are currently available:

1. Mosquito® Liquid

From Slice Engineering, comes the Mosquito Liquid. Slice has a very respected reputation in the 3D printing community and their air-cooled Mosquito is highly regarded. It has a great design, is made of quality parts, and is known to last a long time with very little maintenance. I’m expecting this water-cooled version to be of the same quality.

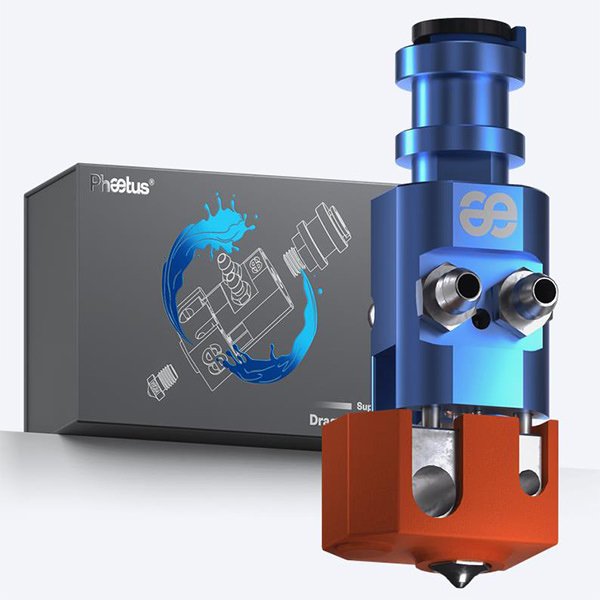

2. Dragon WST

The Dragon from Phaetus is very popular hotend due to its low cost and high performance. It has also been widely adopted into many different mounting/carriage systems so there is no short of options there. This version takes that original design even further. This hotend comes in 2 different options, WST (Water Standard Flow) and WHF (Water High Flow).

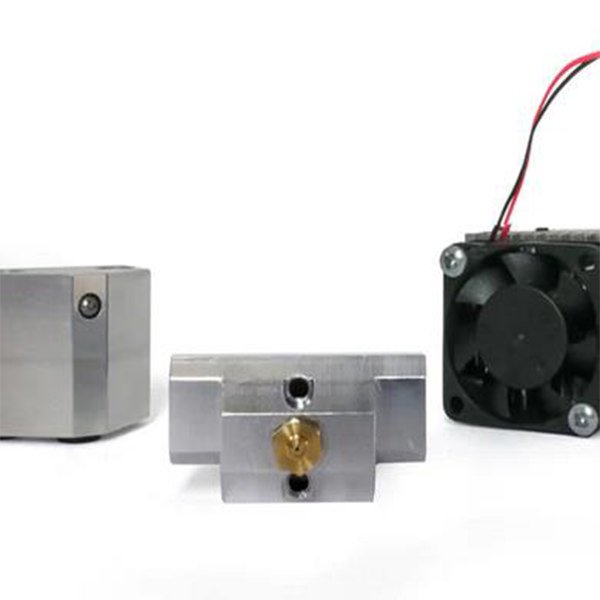

3. E3D

E3D is probably one of the most recognizable brands in the 3D printing space. Their V6 hotend is a hugely respected piece of hardware that can be found as a stock option on many popular 3D Printers. They have several water-cooled options including heatsinks, hotends, and extruder/hotend combos. The Titan Aqua would be the easiest choice as the other options involving dual color and multi-material printing which adds another level of complexity.

Check out the Chimera+ here <—-

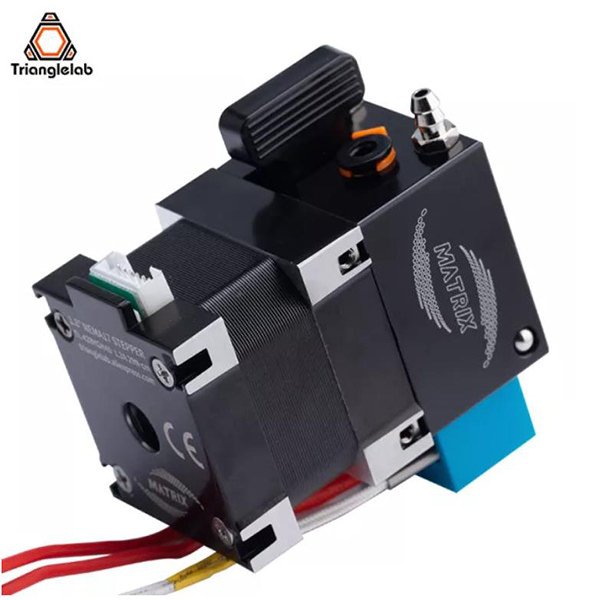

4. Trianglelab Matrix-LC

Trianglelabs is known for replicating many popular hardware pieces from the many prominent 3D printing equipment manufacturers. The Matrix-LC is basically their version of the E3D Titan Aqua. Their prices are usually better and the quality can be either the same or worse. I would do some deeper research if you choose to go this route and see if their is a benefit in buying a clone.

5. Mellow 3D W-DDG

Mellow3D is another company that produces some original parts and some cloned parts as well. Their W-DDG hotend/extruder combo seems to be a mash-up of parts from different hardware. The main benefit in this W-DDG is that it bolts directly onto your Ender 3 printer without the need for additional mounting pieces.

6. Goliath Hotend

The Goliath hotend is one of the best hotends on the market for the pro-consumer. Designed by VzBoT 3D and produced by Mellow3d, this hotend overcomes every challenge one can face and is probably overkill for most users. It’s 550deg max temp, large melt zone, combination of advanced materials, and extremely high volumetric flow rate make it the last hotend that you would ever have to buy.

To go one step further, consider upgrading to the water-cooled VZ-Hextrudort-Low which has integrated water-cooling. This not only cools the hotend but the extruder as well.

Conclusion

It’s a great time for technology in 3D printing right now as there are many companies testing the ‘waters’ with what is possible. There are many great options for a water-cooled hotend with many more on the way, I’m sure.

I hope this article helped shed some light on the water-cooled side of the 3D printing industry. If you need any help or have any questions, feel free to leave a comment below.

HevORT teams up with Mellow 3D to offer modular 3D printer kits, allowing for full customization and control over your printing setup.