Cocoa Press: Crafting Sweetness Layer by Layer

The journey from curiosity to culinary innovation in 3D printing has been long, marked more by novelty than by practical applications. Enter Cocoa Press, a groundbreaking approach that shifts the narrative, turning the idea of 3D-printed edibles from an intriguing sideshow into a mainstage innovation. This system brings everything needed— from the printer itself to specialized nozzles and cocoa cores—to make chocolate printing not only feasible but remarkably simple. Here's a glimpse into how Cocoa Press is blending technology with the artistry of chocolate making, paving the way for a new era of gourmet creativity.

| Cocoa Press Quick Facts | |

|---|---|

| DIY Kit Price | Starts at $1,499 |

| Professional Package Price | Starts at $3,995 |

| Build Volume | 140 x 150 x 150mm (5.5"×6"×6") |

| Heat-up Time | 20 mins |

| Maximum Operating Temperature | 31-32°C (87-89°F) |

| Power Consumption | Peaks at 150W |

| Cocoa Press Quick Links | |

|---|---|

| Official Website | Visit |

| Documentation | Visit |

| Visit on Facebook | |

| Follow on Instagram | |

| YouTube | Subscribe on YouTube |

| TikTok | Watch on TikTok |

| Follow on Twitter | |

Cocoa Press and the Vision Behind Edible 3D Printing

Cocoa Press is revolutionizing the way we think about food and technology, blending the art of chocolate making with the precision of 3D printing. The founder, Ellie, embarked on this innovative journey in 2014 during an introductory engineering class in high school. Her fascination with the potential of 3D printing technology to transform traditional crafts into something extraordinary led her to develop Cocoa Press. After graduating from Penn Engineering in 2019, Ellie dedicated herself full-time to Cocoa Press, turning her passion project into a groundbreaking enterprise.

Ellie's vision for Cocoa Press was not just about creating another 3D printer; it was about opening a new realm of culinary possibilities. She imagined a world where anyone could design and create bespoke chocolate creations at the touch of a button. Her dedication to this vision stems from her broader interest in the potential of 3D printing across various industries. Beyond her work with Cocoa Press, Ellie has showcased her engineering prowess as part of team Mammoth on the Battlebots TV show, demonstrating her commitment to pushing the boundaries of what's possible with technology.

Aside from her technological endeavors, Ellie is a multi-talented individual with a creative soul. Her hobbies include singing, weaving, woodworking, and glassblowing, reflecting her diverse interests and skills. Moreover, Ellie is an active advocate for trans rights across the United States, using her platform to support and champion the rights of the LGBTQ+ community. Her work with Cocoa Press is just one aspect of her multifaceted career, combining her passion for innovation with her commitment to making a positive impact in the world.

At its core, Cocoa Press represents the fusion of technology, art, and activism. It's a testament to Ellie's belief in the transformative power of 3D printing, not just in the culinary world but as a tool for creative expression and social change. Through Cocoa Press, Ellie invites us to explore the delicious possibilities of technology, one layer of chocolate at a time.

A Brief History of 3D Food Printing

The journey of 3D food printing began as an ambitious venture to merge culinary arts with cutting-edge technology. It all started with the hobbyist 3D printing movement, which saw its first major leap forward at Cornell University. Here, researchers developed the Fab@Home printer in 2006, one of the earliest machines capable of printing edible materials like chocolate, cookie dough, and cheese. This innovation laid the groundwork for what would become a new frontier in food preparation and presentation.

Following the footsteps of the Fab@Home project, numerous endeavors sought to explore and expand the capabilities of 3D food printing. One notable example is the ChefJet by 3D Systems, unveiled at International CES 2014. The ChefJet caught the audience's attention with its ability to produce ornate, full-color cake toppers using binder jet technology. However, despite the initial excitement, the ChefJet and similar projects faced challenges in moving from concept to widespread adoption, highlighting the complexities of integrating 3D printing into the culinary world.

Despite these challenges, the exploration of 3D food printing has continued to evolve, with companies and researchers seeking ways to make the technology more accessible and applicable to everyday cooking and professional gastronomy. Innovations have not only focused on sweets and desserts but have also ventured into more complex culinary areas, such as creating personalized nutritional supplements and experimenting with sustainable food sources like insect-based proteins.

The history of 3D food printing is a testament to the ongoing dialogue between technology and culinary tradition, aiming to redefine what's possible in the kitchen. From its experimental beginnings to the present day, 3D food printing remains a vibrant area of exploration, promising a future where food is not only tailored to individual tastes and nutritional needs but also crafted with the precision and artistry that only technology can provide.

How Cocoa Press Works

Cocoa Core

Cocoa Press introduces a seamless integration of technology into the art of chocolate creation. It employs a dedicated chocolate printer, specifically designed to operate within the crucial melting point range of 31-32°C (87-89°F). This precise temperature control is pivotal, ensuring that the chocolate melts properly for printing without compromising its quality, resulting in the perfect texture and luster expected of artisan chocolate.

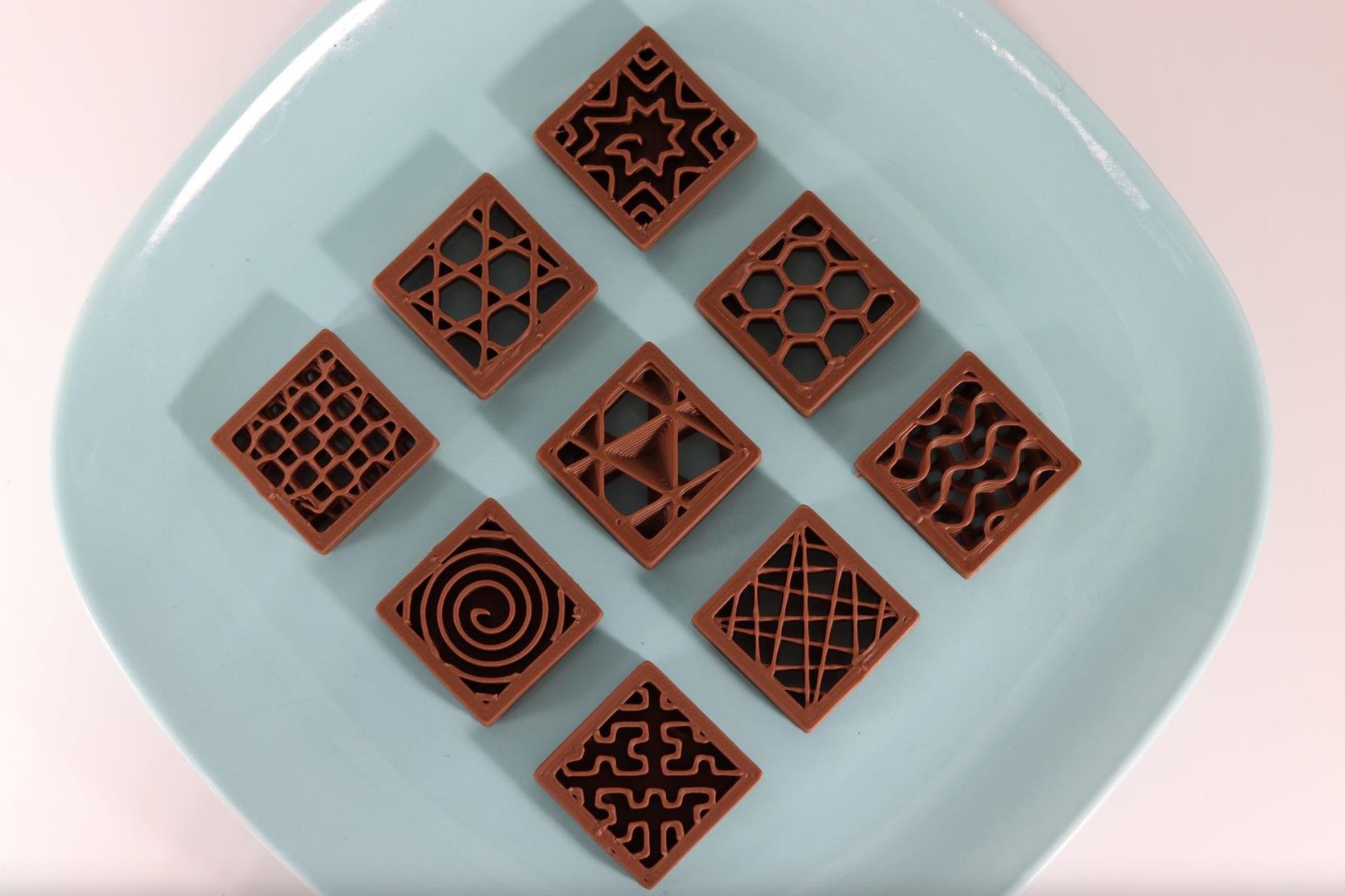

Equipped with cocoa cores—cartridges filled with premium chocolate formulated for 3D printing—the Cocoa Press maintains chocolate at the optimal consistency for printing. These cores, combined with specially engineered nozzles, allow for the precise layering of melted chocolate, building up complex and detailed designs layer by layer on the build platform. The printer's build volume of 140 x 150 x 150mm (5.5"×6"×6") offers ample space for a wide range of creations, from personalized messages to intricate patterns.

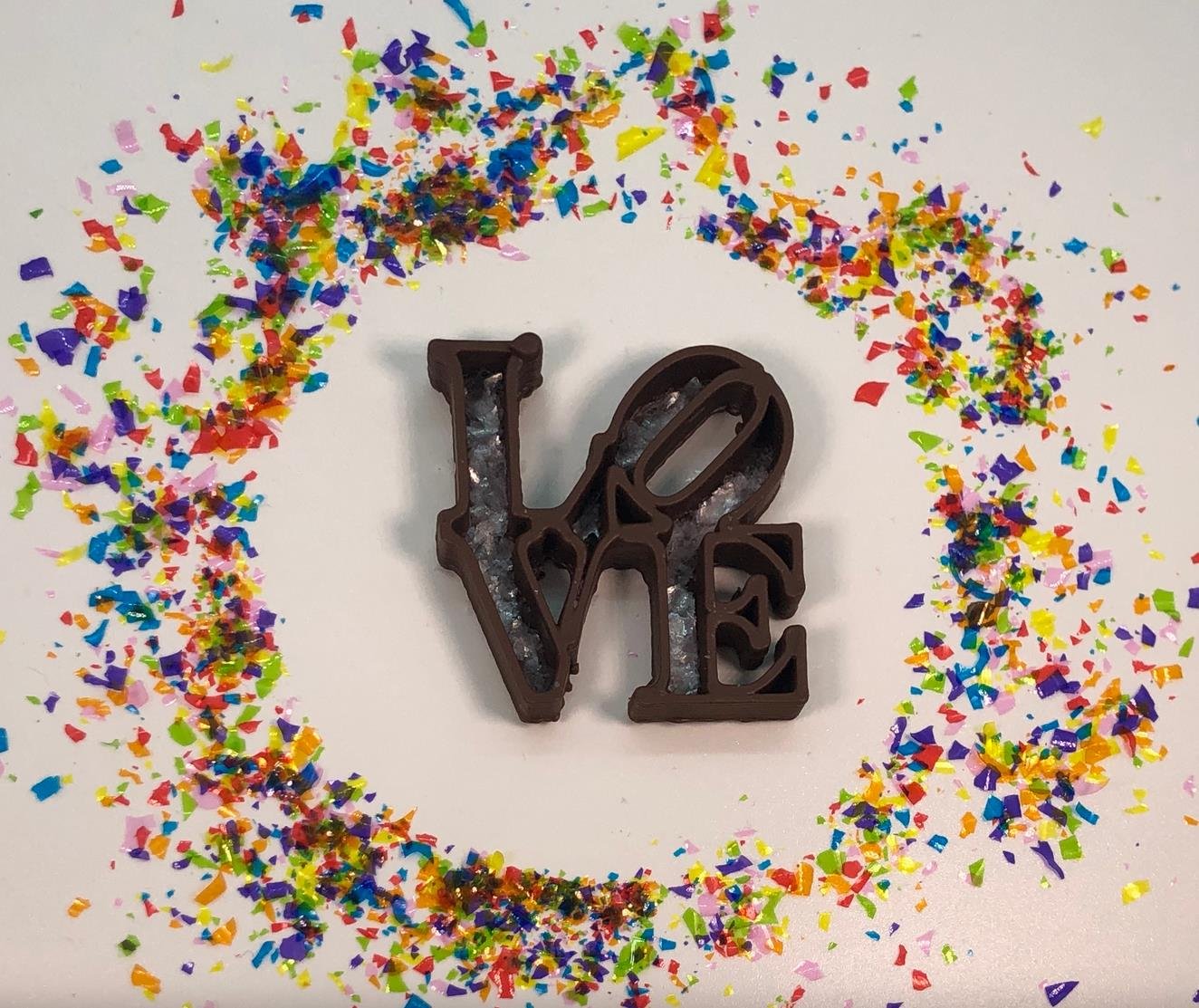

The process from design to chocolate creation involves digital modelling software where users can unleash their creativity, designing anything from personalized messages to intricate patterns. Once a design is finalized, it's sent to the Cocoa Press printer, which meticulously prints the design by carefully extruding the melted chocolate, layer by layer, onto the build platform.

What makes Cocoa Press a game-changer in the chocolate-making and culinary industry is not just its ability to print with chocolate but its precision and the quality of the output. The importance of the melting temperature cannot be overstated; it ensures that the chocolate solidifies correctly after each layer is printed, maintaining the integrity of complex structures and the smooth finish characteristic of high-quality chocolate.

This technology democratizes the chocolate crafting process, opening up new possibilities for customization and creativity. Whether for professional chocolatiers looking to experiment with new designs or hobbyists eager to explore the convergence of technology and culinary arts, Cocoa Press offers an accessible platform to push the boundaries of traditional chocolate making.

Visit Cocoa Press

Whether you're diving into the world of 3D chocolate printing for the first time or looking to expand your culinary arsenal, Cocoa Press offers two distinct packages to suit your needs. The DIY kit, perfect for those who enjoy the hands-on experience of building and customizing their printer, starts at $1,499. For professionals seeking a more comprehensive solution straight out of the box, the professional packages begin at $3,995, designed to cater to the higher demands of a professional setting. Explore the possibilities and bring your chocolate creations to life with Cocoa Press.

FAQ's: The Basics

Where do I get designs?

You'll find pre-made designs on Cocoa Press's platform or explore sites like Thangs or Printables for a wide array of 3D printable files. You can also craft your own designs using most CAD software, as Cocoa Press supports .stl and .3mf file formats, which are standard across all 3D printers.

How easy is it to use?

Cocoa Press is designed to be user-friendly with a simple setup and reliable results. However, like any 3D printing endeavour, there's a learning curve, especially in figuring out which designs work best. Once you've got the hang of the basics, you'll be able to unleash your creativity and bring your chocolate visions to life.

How fast is 3D printing chocolate?

The speed of printing chocolate varies based on the complexity and size of the design, ranging from as little as 5 minutes to up to 2 hours. This allows for personalized designs, small batch orders, and the creation of parts that traditional methods can't achieve.

How difficult is the assembly process?

The DIY kit from Cocoa Press is estimated to take about 10 hours to assemble. It's recommended for those with prior 3D printing experience, although it's noted to be slightly easier than assembling a VORON V0.1 kit. No previous electronics knowledge is necessary, making it a manageable project for most enthusiasts.

How much power does the printer use?

Cocoa Press's printer is designed for efficiency, peaking at 150W. It plugs into a standard 110VAC or 220VAC wall outlet, making it compatible with household electrical systems without requiring special accommodations.

What kind of chocolate does it use?

Cocoa Press uses a special formulation of milk and dark chocolate, designed specifically for 3D printing. This compound chocolate swaps traditional cocoa butter for palm oil, sourced sustainably and certified by the RSPO, ensuring a high-quality print that's also mindful of environmental impact.

Can I use my own chocolate with Cocoa Press?

Yes, you're free to use your own chocolate. While Cocoa Press's cores offer ease and reliability, experimenting with different chocolates is possible, though it may require trial and error to perfect the printing temperature and ensure the chocolate is air bubble-free.

What kind of chocolate is offered?

Currently, Cocoa Press provides dark, milk, and white chocolate cores. Plans to expand the range, including options for vegan white chocolate cores, are underway, showcasing the brand's commitment to catering to diverse dietary preferences and needs.

How do I clean Cocoa Press?

Maintaining Cocoa Press is straightforward. The chocolate touches only four parts, all of which can be easily removed and cleaned without tools. The printer includes all necessary brushes, and it's recommended to use a clean plunger between prints and wash the other components at the day's end to ensure hygiene and longevity of the device.

Related Articles

Get an in-depth look at the QIDI Tech Q1 Pro in our detailed review. Find out how this desktop 3D printer delivers engineering-grade filament printing with unmatched precision, speed, and versatility.