3D Printing Z-Upgrade - Here’s 5 Reasons Why Ballscrews Are Better Than Leadscrews

If you are a 3D printing enthusiast, and you have found this post, then that means you are in search of 3D printing perfection. If you have a 3D printer with a Z-axis on leadscrews, then I’m sure it’s hard not to see the Z-banding once you notice it.

Other than converting your leadscrew setup to a belt-driven one, which may give you another set of problems, your only option is to convert those ancient, old leadscrews to ballscrews.

First, what's the difference between a leadscrew and a ballscrew?

A leadscrew is just a screw with a nut that works in two ways: either the shaft remains still and the power is sent to the nut, or the shaft rotates and supplies the nut with power. In the former case, you either need to physically turn it or put in a motor to rotate the nut, which then causes it to move along the axis of the shaft - turning the torque into linear movement.

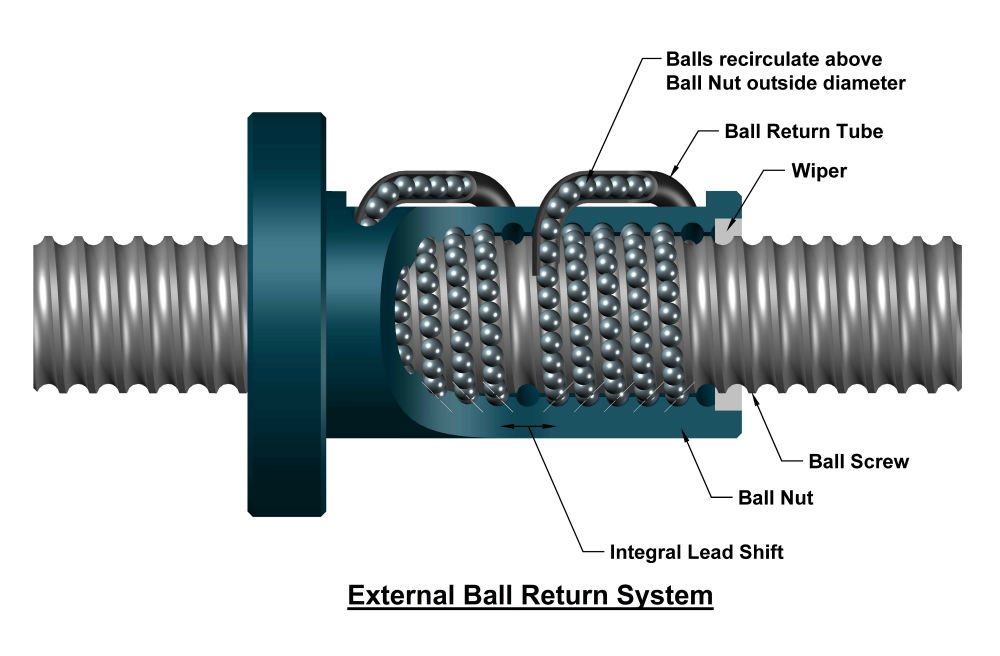

A ballscrew assembly is made up of a screw and a nut that both have matching helical grooves, and some balls that roll between them. As one of them turns, the balls get pushed by a deflector into the nut's ball return system, then move to the opposite end of the nut in a continuous flow. They leave the return system and go back into the screw and nut thread raceways, so they can circulate in a closed path.

So basically, a leadscrew is just a threaded rod with a nut and a ballscrew is a bearing equivalent of a leadscrew. It’s the same as a linear rail, but the groove is in a spiral.

leadscrew on a Rat Rig V-Core 3 3D printer

Here are 5 reasons why ballscrews are generally considered to be superior to leadscrews

Increased Efficiency: Ballscrews have a rolling action between the nut and the screw, which results in less friction and less wear than the sliding action of a leadscrew. This results in a higher efficiency of around 90-95% for ballscrews, compared to around 75-80% for leadscrews.

Higher Accuracy: Because of their rolling action, ballscrews can provide greater positional accuracy than leadscrews. This is because the ballscrew nut can rotate as the screw turns, which helps to distribute any inaccuracies along the length of the screw, resulting in a smoother overall motion.

Greater Thrust Capacity: Ballscrews can support higher loads and thrust capacities than leadscrews, which makes them well-suited for heavy-duty applications such as CNC machines, robotics, and aerospace.

Greater Durability: The rolling action of ballscrews leads to less wear and tear than the sliding action of leadscrews. This means that ballscrews tend to have a longer service life than leadscrews, and can therefore be used in applications where high reliability is critical.

Greater rigidity: Ballscrews have higher rigidity than leadscrews, which means there is less deflection and less play in ballscrews, which is important for precision positioning.

Faint signs of z-banding on a 3D print

Upgrade your 3D printer

If you’re looking to upgrade your machine, the easiest solution is to use Wobble-X. It allows you to convert your standard leadscrews to ballscrews and will give you amazing results. Check out our article on Wobble-X here.

If you are an owner of a Rat Rig V-Core 3, you can check out this article here. It has a few options to allow you to convert your printer to ballscrews.

So if you are chasing perfection in your 3D prints, upgrading from a leadscrew setup to ballscrews is an obvious choice. With greater precision and reliability, after installing ballscrews on your printer you’ll finally be able to move from your z-banding issue and onto the next. Happy searching.

HevORT teams up with Mellow 3D to offer modular 3D printer kits, allowing for full customization and control over your printing setup.