Unlocking the Potential of Resin 3D Printers: An In-depth Guide

Interested in diving into the world of resin 3D printing but don't know where to start? This guide aims to demystify resin 3D printers, their advantages, and how to get the most out of them. Whether you're a beginner or a seasoned pro, we'll take you through the crucial details that will make your 3D printing journey smoother. Let's get started.

Introduction to Resin 3D Printers

As 3D printing technologies advance, resin printers are capturing the spotlight for their unparalleled ability to produce high-resolution and intricately detailed prints. Initially introduced in the 1980s but now more affordable and accessible, these printers are emerging as the go-to option for both hobbyists and professionals. Especially favoured for applications demanding minute detailing—such as tabletop gaming miniatures, jewelry, dental prosthetics, and sophisticated prototypes—resin 3D printers use light-based technologies like Stereolithography (SLA) and Digital Light Processing (DLP) to transform liquid resin into solid, tangible art.

Types of Consumer Resin Printers

SLA (Stereolithography) Printers: The trailblazers of resin printing, SLA printers use a UV laser to etch each layer of an object onto a vat of UV-sensitive liquid resin, causing targeted areas to solidify. The build plate then shifts upward, making room for the next layer. Formlabs is a notable brand in this realm.

DLP (Digital Light Processing) Printers: Sharing similarities with SLA, DLP printers differ primarily in their light source—a digital projector that cures an entire layer of resin simultaneously. This enables faster prints but may slightly compromise the level of detail.

LCD (Liquid Crystal Display) Printers: A more recent addition to the resin printing ecosystem, LCD printers are winning fans with their affordability. Utilizing an LCD screen coupled with a UV LED light, these printers expose and cure layers of resin. Popular models include the Elegoo Mars.

MSLA (Masked Stereolithography) Printers: This is essentially a refined version of LCD printers, optimized for both speed and quality. MSLA harmonizes the best traits of SLA and LCD technologies to deliver quicker, yet detailed, prints.

Understanding the Mechanics of Resin Printers

Regardless of the printer type you opt for, the foundational working principle stays the same—layer-by-layer fabrication to create the final object. The journey begins with a 3D model saved in STL format, which is then 'sliced' into countless 2D layers using specialized software like ChituBox. This 'slicing' essentially converts the 3D design into a series of 2D cross-sections, providing the printer with a roadmap. Upon completion, you obtain a G-Code file that guides the printer on layer creation.

The printer subsequently projects these 2D slices onto the liquid resin, methodically curing it layer by layer. Though the projection technique may differ among printer types, the ultimate objective is consistent: controlled solidification of the resin. Once printing concludes, the model must undergo post-processing, including a wash in a chemical solvent and additional UV curing, to achieve its finalized state.

People want you to do well but not better than them.

Additional Factors to Keep in Mind

Safety First: Given the toxicity of liquid resin, safety protocols like wearing nitrile gloves and a certified respirator are mandatory, not optional.

Cost Implications: Compared to their FDM counterparts, resin printers and their consumables are generally more expensive, a crucial factor to consider before committing to a purchase.

Resolution vs. Speed: Thinner layers yield finer details but require longer print times. Balancing quality and speed based on your needs is pivotal.

Why Choose Resin Over FDM?

When it comes to 3D printing, both FDM (Fused Deposition Modeling) and resin-based printers offer a range of advantages and disadvantages. However, there are certain scenarios where opting for a resin printer could be more beneficial. Here are some compelling reasons to choose resin over FDM:

Higher Resolution and Detail

Resin printers are renowned for their ability to produce highly detailed and intricate models. The level of detail achievable is often superior to what most FDM printers can offer, making resin printing an excellent choice for applications where fine details are crucial, such as jewelry design, dental models, or miniature figures.

Smoother Surface Finish

Resin printers generally produce objects with smoother surface finishes right out of the printer. This is particularly advantageous for aesthetic models or prototypes that require minimal post-processing.

Better Material Properties

Resin materials come in a variety of types tailored for specific applications, including options that simulate the properties of glass, ceramic, or even flexible materials. This allows for greater versatility in terms of the end-use cases of your 3D-printed objects.

Faster Prototyping for Small, Detailed Models

While FDM printers may be faster for large, simple components, resin printers often outpace them when it comes to printing small, detailed parts. This makes resin printing a time-efficient choice for projects that require intricate detailing.

Greater Accuracy

The precision offered by resin printing technologies can be particularly beneficial in fields like engineering and healthcare, where even a small margin of error could lead to significant problems.

Fewer Geometric Limitations

Because of the way resin printing technology works, you can often print complex geometries and internal structures that would be challenging or impossible to achieve with FDM technology, like floating components or intricate lattice structures.

What is Resin?

Resin, often viewed as a form of liquid plastic, is a versatile material that plays a crucial role in the 3D printing realm. Depending on the specific resin type, the properties of the resulting 3D printed objects can vary from stiff to flexible, from rugged to resilient, or even from standard to biocompatible.

Composition and Types of Resin

Navigating the vast realm of 3D printing resins might seem daunting at first. Unlike standard 3D printing materials like PLA or ABS, resins don’t follow a set chemical formula. Each brand boasts its unique blend of monomers, oligomers, and various additives, forming what's known as a photopolymer. Consequently, rather than pinpointing their chemical compositions, resins are often marketed based on functional characteristics like "strong," "flexible," or "tough." And with each brand keeping its formulation under wraps, it can be challenging to compare one resin to another.

For a deeper dive into a specific resin’s properties, always peek at its technical data sheet. It'll offer a clear view of its characteristics and compatibility. Some resins work wonders with particular 3D printing technologies, such as SLA, DLP, or LCD. Meanwhile, others are tailor-made for specific industries. For instance, clear, biocompatible resins often find favour in the dental sector for products like mouthguards, while the jewelry world cherishes high-detail resins compatible with the lost-wax casting process.

To help you get started, here's a quick roundup of popular resin types:

Standard Resins: Ideal for beginners, these versatile resins are great for a range of basic projects. And the best part? They're wallet-friendly.

Tough Resins: If durability is your game, tough resins are your MVP. They’re perfect for parts that need to endure wear and tear.

Flexible Resins: For prints that need a touch of flexibility, these resins are the way to go, making them perfect for items like phone cases.

High-Temp Resins: Projects demanding heat resistance? These resins can take the heat without losing shape.

Castable Resins: Jewelers and artists, rejoice! These resins are designed to burn out cleanly, ideal for crafting intricate pieces.

Water Washable Resins: Say goodbye to tedious IPA clean-ups. A splash of water is all you need with these resins.

Is Resin Harmful?

Despite its versatility, it's essential to treat 3D printing resins with caution. By their nature, these resins are toxic. They can be carcinogenic, irritate the skin, affect respiratory systems, and prove detrimental to the environment. It's imperative to use gloves when handling resin or post-processing resin-printed parts. Additionally, printing in a well-ventilated space can help mitigate the risks posed by resin fumes.

With advancements in technology, some printers are incorporating resin cartridges to reduce direct handling, aiming to minimize mess and potential hazards. Moreover, certain professional-grade machines are equipped with touchless conveyor systems, ensuring a safer transition of parts from the printer to the washer and then to the curing station. For those keen on embracing resin 3D printing, it's advisable to familiarize themselves with safety guidelines and disposal procedures to protect both themselves and the environment.

Cost Implications

The cost of resin can vary significantly based on its type and intended application. Standard 3D printing resins, which are versatile but not tailored for any specific application, might start as low as $14 per kg. These are typically used for visual models. In contrast, specialized resins, such as biocompatible dental resins, can command prices exceeding $1,300 per kg, given their niche applications and stringent requirements.

Understanding Resin Types

When diving into the world of resin 3D printing, it's crucial to understand the different types of resins available and their specific uses. Not all resins are created equal, and each comes with its unique set of properties.

Standard Resins

Standard resins are the most common and are usually suitable for general purpose printing. These resins are affordable and easy to work with but may lack some specialized characteristics like flexibility or transparency.

Engineering Resins

Engineering resins are tailored for high-performance applications. These are ideal for producing functional parts that require higher strength, temperature resistance, or specific mechanical properties.

Dental and Medical Resins

Resins designed for dental and medical applications must adhere to stringent safety and quality standards. They are generally bio-compatible and can be sterilized, making them ideal for creating dental molds or surgical guides.

Specialty Resins

Specialty resins are developed for unique applications like casting, ceramics, or even glow-in-the-dark objects. These resins allow for specialized end-use cases that aren't possible with standard or engineering resins.

Best Practices for Resin Printing

When it comes to resin 3D printing, following certain best practices can make a huge difference in the quality and reliability of your prints. Here are some essential tips:

1. Safety First

Resin can be toxic and should be handled with care. Always wear gloves when handling resin, and work in a well-ventilated area.

2. Leveling the Build Plate

Proper leveling of the build plate is crucial for the success of any 3D print. Take your time during this step to ensure that the first layer adheres well to the build plate.

3. Post-Processing is Key

After the print is completed, it's essential to wash and cure the object properly. Inadequate post-processing can result in a sticky surface and less durable prints.

4. Use the Right Resin

Different resins have different properties and are suited for various applications. Make sure to use the resin that best matches your project's needs.

5. Regular Maintenance

Regularly clean your resin vat and build plate to ensure high-quality prints. Neglecting this step can lead to defects and failures in your prints.

How to Achieve Resin Printing Success

Resin printing can deliver unparalleled detail and precision in 3D printing, but to optimize results, it's vital to understand the various elements that can influence both print quality and duration.

What Influences Printing Time?

Several factors can impact the overall print time:

Layer Count: Directly linked to the number of layers a model has. For instance, a model height and the selected layer thickness will dictate the total layers.

Exposure Time: Monochrome LCD printers can achieve exposure times as brief as two seconds. However, RGB screen printers might require 6-12 seconds, depending on the resin utilized.

Layer Height: Resin printers, known for their exceptional detail, operate with extremely thin layer heights, such as 20 or 50 microns. Because of this thinness, despite printing a full layer simultaneously, they can sometimes be slower than FDM printers.

Lift Speed: The lift speed chosen in your slicer software can also alter the total print time. Reducing this speed might reduce the risk of prints detaching from the build plate or supports, but it also lengthens the print duration.

Exposure Times and Resin Prints

Achieving superior prints from a resin printer hinges primarily on the layer exposure time:

Over or underexposing your prints can result in a loss of model detail. It's crucial to calibrate the correct layer time for the specific resin you're using. Most resin producers provide guidelines on exposure times for their products, and many 3D printing communities offer online resources detailing exposure times for various resin brands across different printer models.

While using manufacturer data or online community guidelines can be beneficial, conducting a resin calibration test for your specific printer is highly recommended. The Multi Printer Resin Exposure Test is a valuable resource in this respect. This test involves using three specific files from a Git repository: two G-Code files to configure your printer and a model file for calibration.

The calibration test prints a card showcasing several images and numerical values. These numbers, positioned atop the card, denote exposure times in seconds. Beneath each number is a set of symbols, helping users determine the appropriate layer exposure time for their resin.

For instance, a calibration test conducted for Elegoo standard on an Elegoo Mars printer revealed certain exposure times. Although a visual inspection might indicate one setting as optimal, the actual print can sometimes suggest a slightly different, more suitable exposure time. The objective is to strike a balance where positive and negative spaces on the print are evenly distributed.

Calibration Tests

To be able to print parts successfully, one of the first steps to achieve impeccable print quality is to run a calibration test. Think of it as giving your printer a routine check-up. Calibration prints are specially designed 3D models that help you identify and correct potential issues with your printer's settings.

Using a calibration print is akin to a doctor using a stethoscope – it helps diagnose the problem. Once you've printed the calibration model, you'll inspect it for any irregularities or inconsistencies, such as warping, layer lines, or imperfections. The model's intricacies and details serve as a reference, enabling you to adjust your printer's settings like exposure time, layer height, or lift speed to perfection. By tweaking these settings based on the calibration print's outcome, you're setting the stage for smoother, more accurate, and consistent prints in the future.

Remember, while many resin printers come with 'recommended' settings, every machine can be slightly different. So, running a calibration test and adjusting based on its results is key to unlocking the best performance from your device. Once you've got the hang of it, you can dive into the world of resin printing with confidence.

Calibration Tests:

Curing Resin Prints

After you've successfully printed a resin model, the job isn't finished. Curing your print is an essential final step. When your print is freshly removed from the printer, the resin is still somewhat soft and can be easily damaged. Curing hardens the print, maximizing its durability and bringing out its final properties.

How to Cure Resin Prints

1. Wash the Print: Before curing, it's crucial to clean the print to remove any uncured resin. This can be done using isopropyl alcohol (IPA) or other specialized cleaning solutions. Gently agitate the print in the solution to loosen and remove excess resin.

2. Air Dry or Use Compressed Air: After washing, allow the print to air dry, or you can expedite the process using compressed air.

3. UV Curing: Resin prints are cured using UV light. You can either use a UV curing chamber or, on a sunny day, place your print outside. However, using a curing chamber ensures consistent UV exposure.

4. Curing Time: The amount of time needed to cure a print can vary based on the resin type and the UV light's intensity. As a general guideline, 2-4 hours in direct sunlight or 30 minutes to an hour in a UV chamber should suffice for most prints.

Tips for Successful Curing

Rotate Your Prints: For even curing, make sure to rotate your prints if you're using natural sunlight.

Safety First: Always handle resin with gloves, and consider using safety goggles. Uncured resin can be harmful if it comes into contact with skin or eyes.

Monitor Curing Times: Over-curing a print can make it brittle. Make sure to follow the manufacturer's guidelines regarding curing times.

Storing Resin: Best Practices

Given that resin can be sensitive to environmental factors, proper storage is essential.

1. UV Protection: Store your resin in a dark place. Resin is sensitive to UV light, which can prematurely harden it.

2. Temperature: Resin should be stored at room temperature. Too cold, and it can become viscous and hard to work with. Too hot, and it may reduce its shelf life.

3. Seal Tight: Make sure to seal the bottle tightly after use. This prevents contamination and prolongs the resin's life.

4. Shake Before Use: If the resin has been sitting for a long time, give it a good shake before using it to ensure all the components are mixed properly.

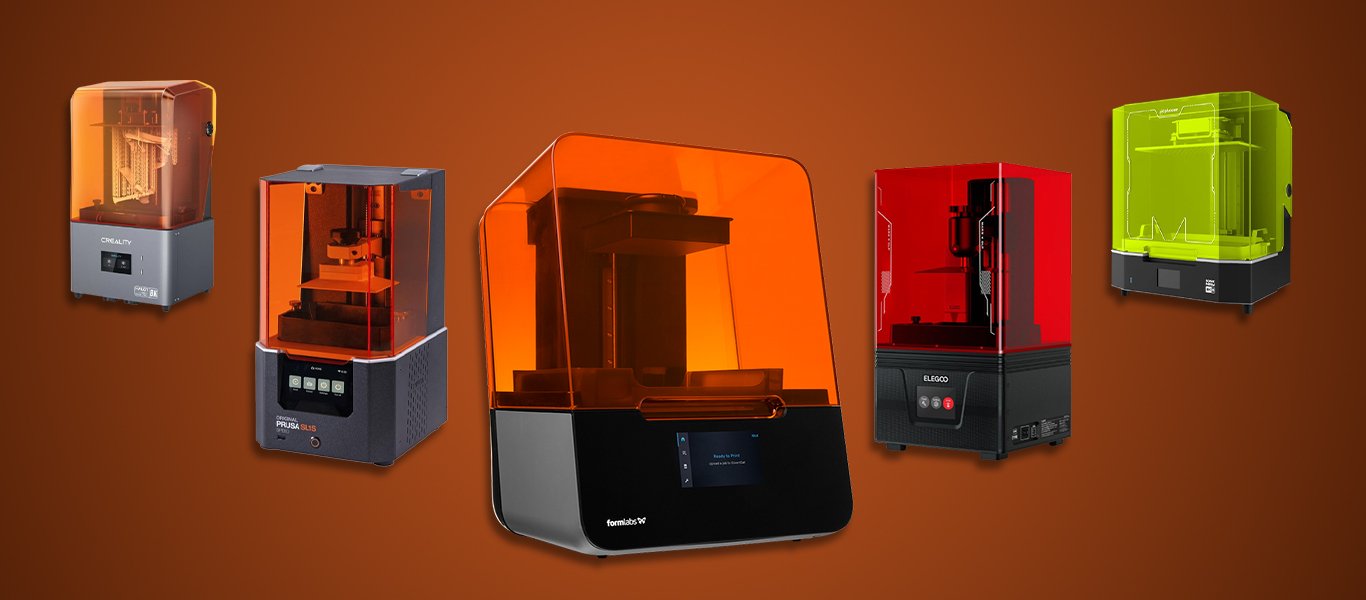

Top Resin Printers to Consider

Selecting the right resin printer can be a daunting task given the variety of options available on the market. Here are some top picks to help you make an informed decision:

Prusa SL1S - Best Prosumer

Prusa Research's SL1S bridges the gap between professional and consumer printers seamlessly. Offering high-quality prints with a focus on user experience, the SL1S is a dream for enthusiasts looking for a premium experience without delving deep into the professional price range.

Pros:

High-resolution printing ensuring detailed output.

User-friendly interface suitable for enthusiasts and semi-pros.

Robust build quality.

Active community and consistent software updates from Prusa.

Cons:

Pricier than some mid-range models.

Slight learning curve for complete beginners.

Creality Halot-Mage Pro 8K - Best Value

When it comes to pushing boundaries in resin printing resolution, Creality’s Halot-Mage Pro 8K is a game-changer. Boasting an astounding 8K resolution, this printer ensures even the minutest details are captured with precision. Its expansive build volume paired with high-speed printing capabilities makes it an excellent choice for hobbyists and professionals seeking top-tier quality without the sky-high price tag.

Pros:

Incredible 8K (7680x4320) resolution for unmatched detail capture.

Generous build volume of 228x128x230mm, making it versatile for larger prints.

Multi-transfer methods: USB, RJ45 cable, WiFi, and even Creality Cloud.

Equipped with a smart resin pump and air purifier, enhancing user experience and safety.

Compatibility with various slicing software including HALOT BOX, CHITUBOX, and Lychee Slicer.

Cons:

Might be overkill for beginners or those not requiring ultra-high resolution.

Given its capabilities, it may require more maintenance than simpler models.

Anycubic Photon Mono M5s - Best High-Resolution

The Anycubic Photon Mono M5s is a top-tier choice for those seeking exceptional detail in their prints. With its 12K resolution and 19-micron X accuracy, it delivers unmatched clarity. Moreover, its impressive speed, reaching up to 105mm/hour, is complemented by the unique auto-leveling feature, eliminating manual calibration hassles. When paired with its specialty high-speed resin, this printer offers swift outputs without sacrificing precision.

Pros:

Stunning 12K resolution for incredibly detailed prints.

Speedy performance with an average print speed of 105mm/hour.

Features auto-leveling using mechanical sensors, ensuring hassle-free setup.

Supports a specialty high-speed resin for faster prints.

Cons:

The release film tends to have a shorter lifespan.

Specialty resin, which enhances performance, comes at a steeper price.

Elegoo Mars 4 DLP - Premier DLP Choice

The Elegoo Mars 4 DLP 3D printer stands out by utilizing digital light processing (DLP) technology instead of the more common MSLA. This printer claims up to 95% light uniformity and reduced light diffusion due to tempered glass, further enhancing print quality with anti-aliasing algorithms. With a resolution of 2560 x 1440 voxels, its design is compact, featuring an anti-UV protective cover. The 3.5-inch touchscreen interface is user-friendly, and its fanless design ensures quieter operations compared to other printers.

Pros:

Uses DLP Technology which offers better energy consumption, less light bleed, and a longer-lasting light source.

Provides uniform light projection for more accurate and detailed models.

Has a compact design suitable for desktop use.

Operates quietly due to its fanless design.

Cons:

Has a limited build volume due to the plate size.

There are potential concerns regarding native resolution.

The included air purifier may be inadequate for larger rooms or extended printing sessions.

Peopoly Phenom Forge - Most Versatile

The Peopoly Phenom Forge is an MSLA 3D printer offering a significant build volume of 288 x 163 x 350mm and a high contrast 6K monochrome panel for improved resolution. It supports multiple slicers, offers remote monitoring through WiFi and an infrared camera, and ensures consistent printing with its temperature-controlled vat. The printer requires 30-60 minutes of assembly and is designed for efficiency and customization.

Pros:

Large build volume and high-resolution 6K monochrome panel.

Multiple slicer compatibility and remote monitoring features.

Temperature-controlled vat for consistent printing.

Easily accessible components for quick maintenance.

Cons:

Requires assembly upon delivery.

Panel lifespan dependent on recommended resin use.

Relatively heavy, making setup or movement challenging.

Potential for frequent component swapping based on usage.

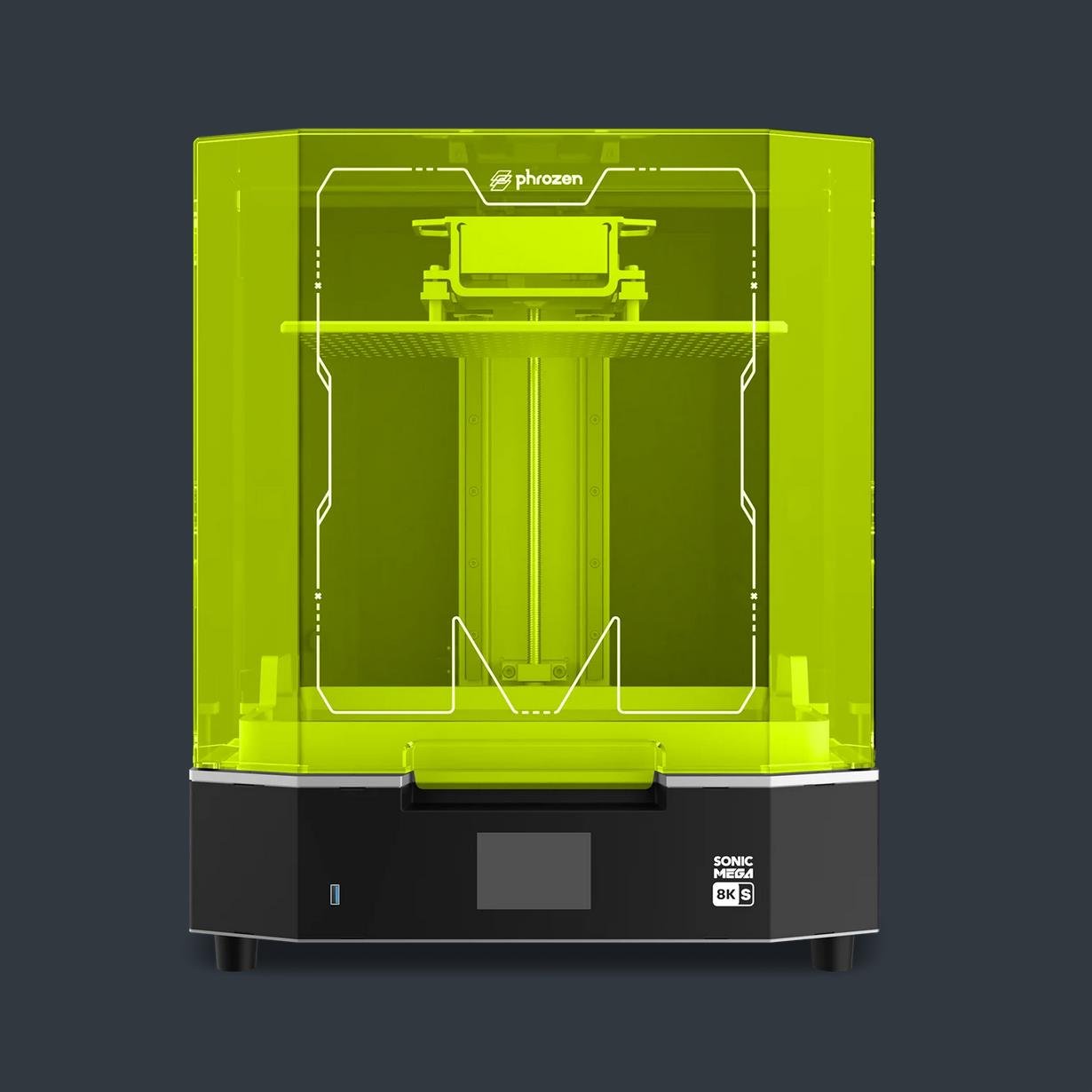

Phrozen Sonic Mega 8K S - Best Large Build Volume

Phrozen's Sonic Mega 8K, a groundbreaking desktop resin 3D printer, boasts an expansive build volume of 330 x 185 x 400 mm and is the first of its kind to incorporate an 8K mono panel with a 15-inch LCD screen. This results in a print resolution of 43 microns, offering users unparalleled detail. Priced at around $1,600, it's more affordable than other large resin printers with the bonus of a higher resolution. It comes with a factory-leveled print plate, which makes the setup process smoother for beginners.

Pros:

Exceptionally large print volume paired with high-resolution 8K screen.

Competitive pricing for its size and features.

Factory-leveled print plate ensures easy setup and consistent results.

Monochrome screen facilitates faster layer cure times and offers a longer lifespan.

Cons:

Increased print volume can lead to more complications.

Lacks certain convenience features found in other models.

Slower print speed compared to other resin printers.

The perforated print plate can result in resin spillage and added cleanup.

Formlabs Form 3+ - Best Professional

Formlabs, a trailblazer in professional 3D printing solutions, delivers the Form3+ as its crown jewel. With precision engineering and a design focused on delivering impeccable results, the Form3+ is tailored for industries and professionals where compromise isn't an option.

Pros:

Industry-leading print quality and resolution.

Extremely reliable for bulk and critical print tasks.

Comprehensive support and warranty from Formlabs.

Modular components for easy replacement and maintenance.

Cons:

Premium price point, making it an investment.

Requires a dedicated workspace due to its size and setup.

Must-Have Resin Printing Accessories

Venturing into the world of resin 3D printing is an exciting endeavor. However, it's vital to be well-equipped with the right tools and accessories to ensure a smooth and safe printing experience. Here's a list of essential items that every resin 3D printing enthusiast should have on hand:

1. Nitrile Gloves: Protecting your hands from direct contact with the resin is crucial. Nitrile gloves are chemical-resistant and provide an excellent barrier against potential resin spills and splashes.

2. Certified Respirator: Given the fumes and vapors that can emanate from the resin, a certified respirator helps ensure you're not inhaling any harmful substances.

3. UV Curing Chamber: After printing, your models will need post-processing under UV light to fully harden. A UV curing chamber or UV lamp will get the job done efficiently.

4. Isopropyl Alcohol (IPA) or Resin Cleaning Solution: This is used to clean and wash your prints after they come out of the printer, ensuring all uncured resin is removed.

5. Soft Brushes: These are handy for gently brushing off excess resin or cleaning solution from your printed models.

6. Silicone Mat: Working over a silicone mat helps protect your workspace from accidental resin spills, making cleanup easier.

7. Plastic Spatula or Scraper: Essential for safely removing prints from the build plate without damaging them.

8. Fine Mesh Strainers: Useful for filtering out any cured bits when pouring unused resin back into its container, ensuring a clean resin for the next print.

9. Plastic or Glass Containers: These are required for the cleaning and washing process, allowing you to submerge your prints in IPA or cleaning solution.

10. Tweezers and Pliers: Helpful for removing support structures or handling small, intricate parts of a model.

11. Safety Goggles: To protect your eyes from potential resin splashes, especially when mixing or pouring.

Choosing the Best Resin

Here’s a short list of some of the most popular resins that are on the market:

Sunlu Water-Washable Resin - A very popular option in the figurine printing world. It’s great for the price + quality.

Use coupon code: IGA5JDZLP0 Buy from Sunlu- Click Here

2. Elegoo ABS-Like Resin - Another popular option that many users to find more durable than standard resin.

3. Anycubic Resin - Great all-around resin at a great price.

4. Siraya Tech Fast ABS-Like Resin - Popular amongst users who are looking for speed and strength.

Slicing Software for Resin 3D Printers

Slicing software plays an integral role in the 3D printing process, acting as a bridge between digital designs and tangible 3D printed models. While those familiar with filament 3D printers may understand the basic concept of slicing, it's essential to note that software designed for FDM machines isn't compatible with resin 3D printers.

How Does Resin Slicing Differ?

For resin 3D printing, the slicing software doesn't generate G-code files like its FDM counterparts. Instead, it produces a series of images that correspond to each layer the printer will cure. This software not only dictates fundamental printing parameters but also oversees the formation and positioning of support structures, pivotal in ensuring the model's integrity and accuracy.

Historically, users predominantly relied on the default slicer bundled with their printers or one released by the same manufacturer. However, with the evolution of the 3D printing landscape, third-party slicers have emerged, offering compatibility with various resin printers and introducing enhanced functionalities.

Among the prominent slicers in the industry, there's a mix of manufacturer-specific and universal software options. Solutions like ChiTuBox and Lychee are notable for their adaptability to various printer models and resin types. With ChiTuBox, for instance, users can tailor their settings by providing printer and resin details, and the software, in turn, offers recommendations based on a comprehensive database to guarantee the finest print quality.

However, it's essential to recognize that high-end, professional resin 3D printers often necessitate their proprietary slicing software. Many of these aren't compatible with universal slicers like ChiTuBox or Lychee. Yet, some can seamlessly integrate with build preparation software embedded within CAD platforms, such as Fusion 360.

| Slicer | Price | OS | Pros | Cons |

|---|---|---|---|---|

| CHITUBOX Free | Free, Paid Pro | Windows 32/64, Mac, Linux |

- Fast slicing speed - Supports STL files and compatible with most resin 3D printers - Good UX - Good for generating supports for resin prints - Automatically arranges parts efficiently |

- Requires an account to download |

| PreForm | Free | Windows 64, Mac |

- Very good at generating resin part supports - Works very well with Formlabs 3D printers - Simple to navigate and use |

--- |

| Z-Suite | Free | Windows 32/64, Mac |

- A one-way operation process UX from importing print to slicing it - A number of strong effective and advanced functions - Comprehensive display information - Comes with a self-built model library |

- The menu layout could be improved |

| PrusaSlicer | Free | Windows, Mac, Linux |

- Clear, if basic UX - Supports STL file export - Experienced in 3D printing having dominated the RepRap 3D printer industry for years - Large community of Prusa users |

- UX could be considered dated |

| FormWare 3D | $149.95 for 1 PC license | Windows only |

- Advanced support generation and editing - Specialized for 3D-printed jewelry applications |

- Expensive - Beginners could find it difficult to use |

| Lychee Slicer | Free, Paid Pro Version | Windows, Mac, Linux, Raspberry Pi |

- Raspberry Pi compatibility (and Mac/Linux/Windows) - Wide resin printer compatibility |

- Pro version costs $6/month |

| Photo Workshop | Free | Windows, Mac, Linux |

- Ideal resin LCD slicer for Anycubic Photon 3D printers - 100% free |

- Less useful to non-Photon machines |

| Nano 3 | Free | Windows, Mac, Linux, Raspberry Pi | - Versatile controller and slicer | - Beginners may find it complex |

| B9Creator | Free | Windows 32/64, Mac |

- Customized supports - Easy editing process for parts |

- Fewer updates - UX could be improved |

Resin 3D Printing Applications and Advancements

As 3D printing technology matures, the potential applications of resin printing expand beyond hobbyists and into more specialized and professional fields. The detailed precision, versatility, and ability to customize on the fly make resin 3D printing an appealing option for various industries.

Resin Printing in Manufacturing

Resin 3D printing's innovation isn't limited to design or consumer products; it's also carving a niche in manufacturing, especially with its capacity to produce intricate lattice structures. A noteworthy example is the collaboration between Carbon, a resin printer manufacturer, and Riddell, a sports equipment enterprise. Together, they've pioneered the production of American football helmets using resin 3D printing. Instead of traditional foam, these helmets utilize 3D printed lattice structures, showcasing superior impact absorption capabilities. This innovative application underscores the versatility of resin 3D printing, achieved, in part, through specialized lattice software.

Medical and Dental Applications

Dental Aligners and Retainers: Custom dental aligners and retainers are crafted using clear biocompatible resins.

Surgical Guides: Surgeons use resin-printed surgical guides for intricate procedures, ensuring precision during operations.

Hearing Aids: Many modern hearing aids are crafted using resin 3D printing, ensuring a perfect fit for the user.

Jewelry Making

Lost-Wax Casting: Jewelers utilize specific resins that burn out cleanly to create intricate patterns and molds for precious metals.

Prototyping: Before the final piece is made, a resin prototype helps clients visualize the final product.

Art and Sculpture

Fine Details: Artists use resin printing to achieve details that might be hard to capture with other 3D printing methods.

Art Replicas: Museums and institutions can produce high-fidelity replicas of valuable or fragile artworks for study or display.

Eyewear

Custom Frames: Bespoke eyewear brands use resin 3D printing to create customized eyeglass frames tailored to individual facial structures.

Automotive and Aerospace

Prototyping: Before final production, resin printing helps engineers visualize parts and components.

Custom Interiors: High-end car and aircraft manufacturers use resin printing for specialized interior components.

Education

Anatomical Models: Medical schools utilize detailed resin-printed human organs and systems for teaching.

Archaeological Replicas: Educational institutions can recreate ancient artifacts for hands-on study without risking the original items.

Entertainment and Gaming

Miniatures and Figurines: Tabletop gamers and collectors appreciate the fine detail and customization that resin printing offers for miniatures.

Prop Creation: Film and television industries use resin printers to quickly fabricate detailed props for on-screen use.

Fashion

Accessories: Designers experiment with unique patterns and designs for items such as earrings, necklaces, and other wearable art using resin 3D printing.

Footwear: Some innovators are exploring resin 3D printing for creating customized shoe soles or intricate heel designs.

Conclusion

3D printing with resin offers numerous advantages from higher resolution and detail to better material properties. Whether you are a hobbyist or a professional, understanding the types of resin, best practices, and essential accessories can significantly enhance your 3D printing experience. With the right printer and know-how, the possibilities are endless.

Related Articles

Get an in-depth look at the QIDI Tech Q1 Pro in our detailed review. Find out how this desktop 3D printer delivers engineering-grade filament printing with unmatched precision, speed, and versatility.