Bambu Lab A1 Mini Review: Speedy, Compact, and Simple 3D Printing

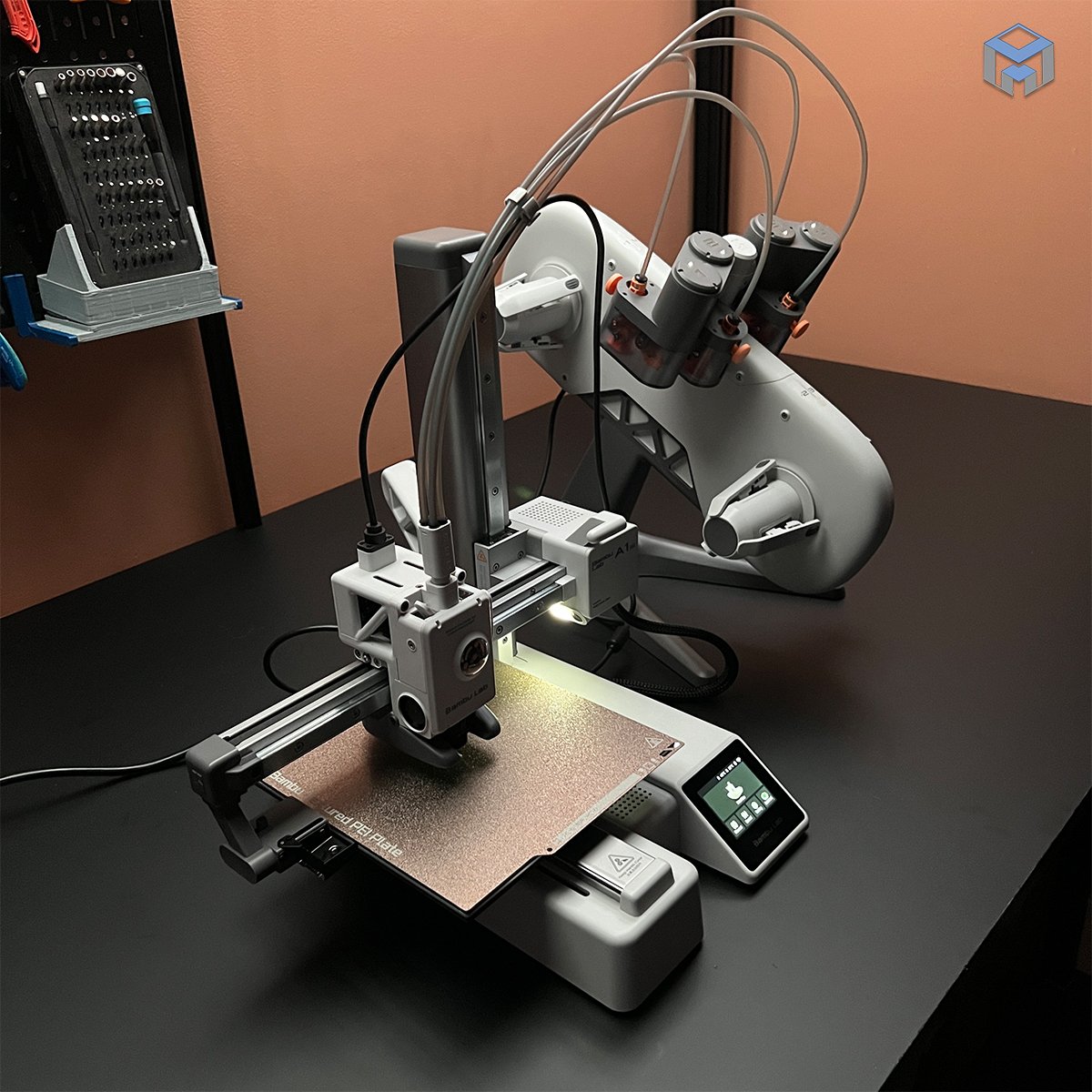

The Bambu Lab A1 Mini 3D printer is a compact yet speedy machine tailored for both newcomers and experienced makers. Its size makes it a convenient choice for any workspace, while its speed doesn’t compromise the quality of prints. In exploring the Bambu Lab A1 Mini, we’ll touch on its features, performance, and its place in your 3D printing journey. It's a glimpse into how this printer holds up in the competitive market of consumer 3D printing.

| Bambu Lab A1 Mini Quick Facts | |

|---|---|

| Printer Price | $299 USD |

| Price with AMS Lite | $459 USD |

| Build Volume | 180*180*180 mm³ |

| Max Speed | 500mm/s |

| Max Acceleration | 10000 mm/s² |

| Official Store | Click Here |

The Story of Bambu Lab

Bambu Lab Founders (Source: Bambu Lab Blog)

Bambu Lab's journey began with a team deeply rooted in DJI drones, united by their shared enthusiasm for 3D printing. Their initial collaboration unfolded during a 3-day retreat, where intense technical discussions laid the groundwork for Bambu Lab's vision. This retreat marked the inception of their endeavour, which soon transitioned into a successful Kickstarter campaign. The campaign not only achieved its funding target but emerged as one of the most triumphant technology campaigns on the platform, reflecting the public's eagerness for Bambu Lab's innovative approach to 3D printing.

The funds from the Kickstarter launched them into the consumer 3D printing market with the introduction of the X1C. This printer quickly became a favourite among 3D printing enthusiasts, marking Bambu Lab's strong entry into the market. The X1C was a pioneer in the consumer 3D printing market, marking the first time a company had focused on creating a seamless and enjoyable user experience, bringing 3D printing closer to being a household appliance.

Building on the success of the X1C, Bambu Lab introduced the P1P, a simplified version of the X1, focusing on essential features while maintaining quality. Following the P1P, they launched the P1S, an even more streamlined model with a lower price tag, aiming to attract new users to 3D printing. The evolution of these models led to the creation of the A1 Mini. This latest model encapsulates the lessons learned from the entire lineup, presenting a compact, fast, and user-friendly 3D printing solution, making 3D printing more accessible than ever.

The story of Bambu Lab is about more than just creating printers; it's about propelling consumer 3D printing forward. The A1 Mini represents a significant stride in that direction, showcasing Bambu Lab's ongoing commitment to delivering valuable 3D printing solutions to consumers.

Unboxing and Setup

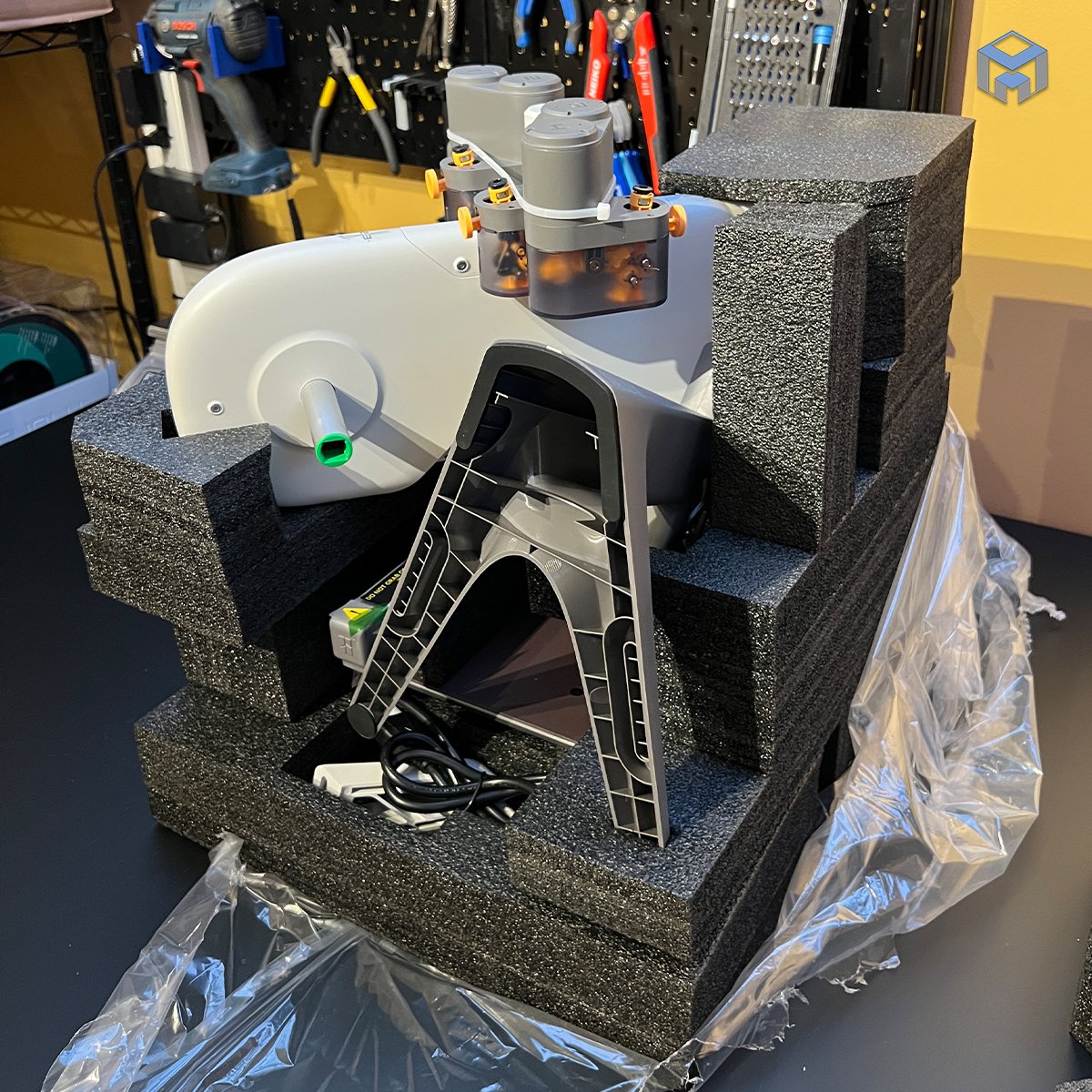

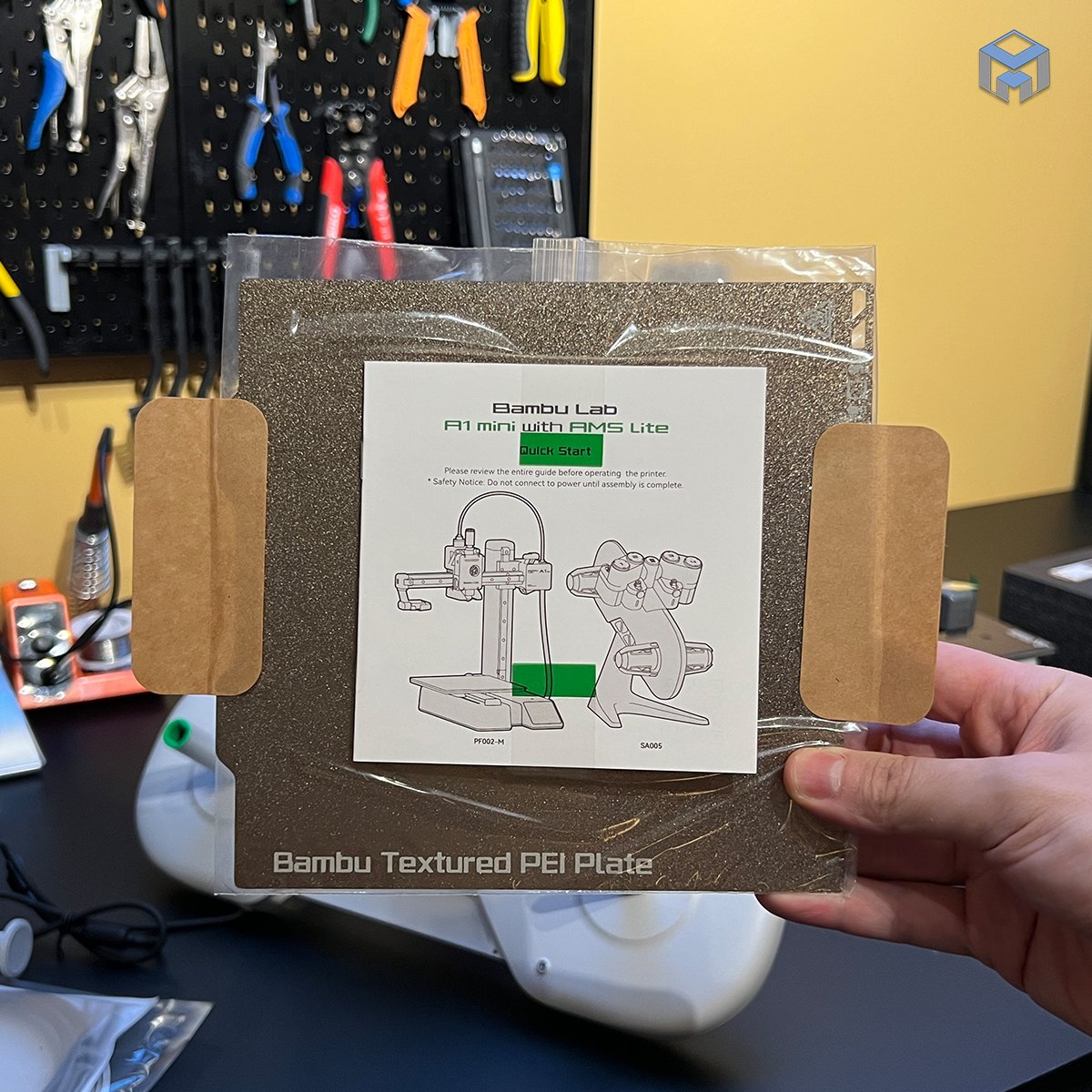

Unboxing the Bambu Lab A1 Mini introduces you to a user-centric experience right from the start. The secure packaging ensures the printer reaches you in impeccable condition. Within the box, you'll discover the printer, essential accessories like the textured PEI plate, some sample filament, and a helpful setup guide.

Setting up the A1 Mini is straightforward. It arrives nearly fully assembled, drastically reducing the setup time. The clear instructions provided guide you effortlessly through the setup process, having you operational in no time. The manual delineates each step, from removing the z-axis limiter, which safeguards the printer during transit, to attaching the accessories and cables.

Upon powering up, an organized touchscreen interface welcomes you. The intuitive menu facilitates a smooth start for both novices and experienced makers. Initially, you’ll be directed through calibration tests ensuring your printer is primed for high-quality, high-speed printing.

The ease of setup mirrors Bambu Lab's ethos—making 3D printing accessible without a daunting learning curve. This approach lowers the entry barrier for newcomers while enabling seasoned makers to dive into printing without delay.

The setup process stands out as the most straightforward, enjoyable, and quickest I’ve ever experienced with a 3D printer. There’s no prerequisite knowledge required to assemble this printer. You simply attach a few accessories, connect some cables, and power it on. This ease nudges the A1 Mini closer to being an appliance in the consumer 3D printing domain.

Specifications and Features

The Bambu Lab A1 Mini is a blend of compactness and high-speed performance, housing robust features in its small frame. Here are the key specifications and features that make this printer a noteworthy contender in the consumer 3D printing market.

Technical Specifications

| Item | Specification | |

|---|---|---|

| Body | Build Volume (WxDxH) | 180x180x180mm |

| Chassis | Steel + Extruded Aluminum | |

| Toolhead | Hotend | All-Metal |

| Extruder Gears | Steel | |

| Nozzle | Stainless Steel | |

| Max. Hotend Temerature | 300°C | |

| Nozzle Diameter (Included) | 0.4mm | |

| Nozzle Diameter (Optional) | 0.2mm / 0.6mm / 0.8mm | |

| Filament Cutter | Yes | |

| Filament Diameter | 1.75mm | |

| Heatbed | Compatible Build Plate | Bambu Textured PEI / Bambu Smooth PEI Plate |

| Max. Build Plate Temperaute | 80°C | |

| Speed | Max. Speed Of Toolhead | 500 mm/s |

| Max. Acceleration Of Toolhead | 10 m/s² | |

| Max. Hotend Flow | 28 mm²/s @ ABS (Model: 150*150 Single Wall; Material: Bambu ABS; Temp: 280°C) | |

| Cooling | Part Cooling Fan | Closed Loop Control |

| Hotend Fan | Closed Loop Control | |

| MC Board Cooling Fan | Closed Loop Control | |

| Suported Filament | PLA, PETG, TPU, PVA | Ideal |

| ABS, ASA, PC, PA, PET, Carbon/Glass Fiber Reinforced Polymer | Not Recommended | |

| Sensors | Monitoring Camera | Low Rate Camera (up to 1080P) Timelapse Supported |

| Filament Run Out Sensor | Yes | |

| Filament Odometry | Yes | |

| Power Loss Recover | Yes | |

| Filament Tangle Sensor | Yes | |

| Physical Dimensions | Dimensions (WxDxH) | 347 x 315 x 365 mm³ |

| Net Weight | 5.5kg | |

| Electrical Requirements | Input Voltage | 100-240 VAC, 50/60 Hz |

| Max. Power | 150 W | |

| Electronics | Display | 2.4 inches 320*240 IPS Touch Screen |

| Connectivity | WiFi, Bambu-Bus | |

| Storage | Micro SD Card | |

| Control Interface | Touch Screen, APP, PC Application | |

| Motion Controller | Dual-Core Cortex M4 | |

| Software | Slicer | Bambu Studio / Support 3rd Party Slicers Which Export Standard G-Code Such As SuperSlicer, PrusaSlicer And Cura, But Certain Advanced Features May Not Be Supported |

| Slicer Supported OS | MacOS, Windows | |

| Wi-Fi | Frequency Range | 2412 MHz - 2472 MHz (CE) / 2412 MHz - 2462 MHz (FCC) / 2400 MHz - 2483.5 MHz (SRRC) |

| Transmitter Power (EIRP) | ≤21.5 dBm (FCC) /≤20 dBm (CE/SRRC) | |

| Protocol | IEEE 802.11 b/g/n | |

Features

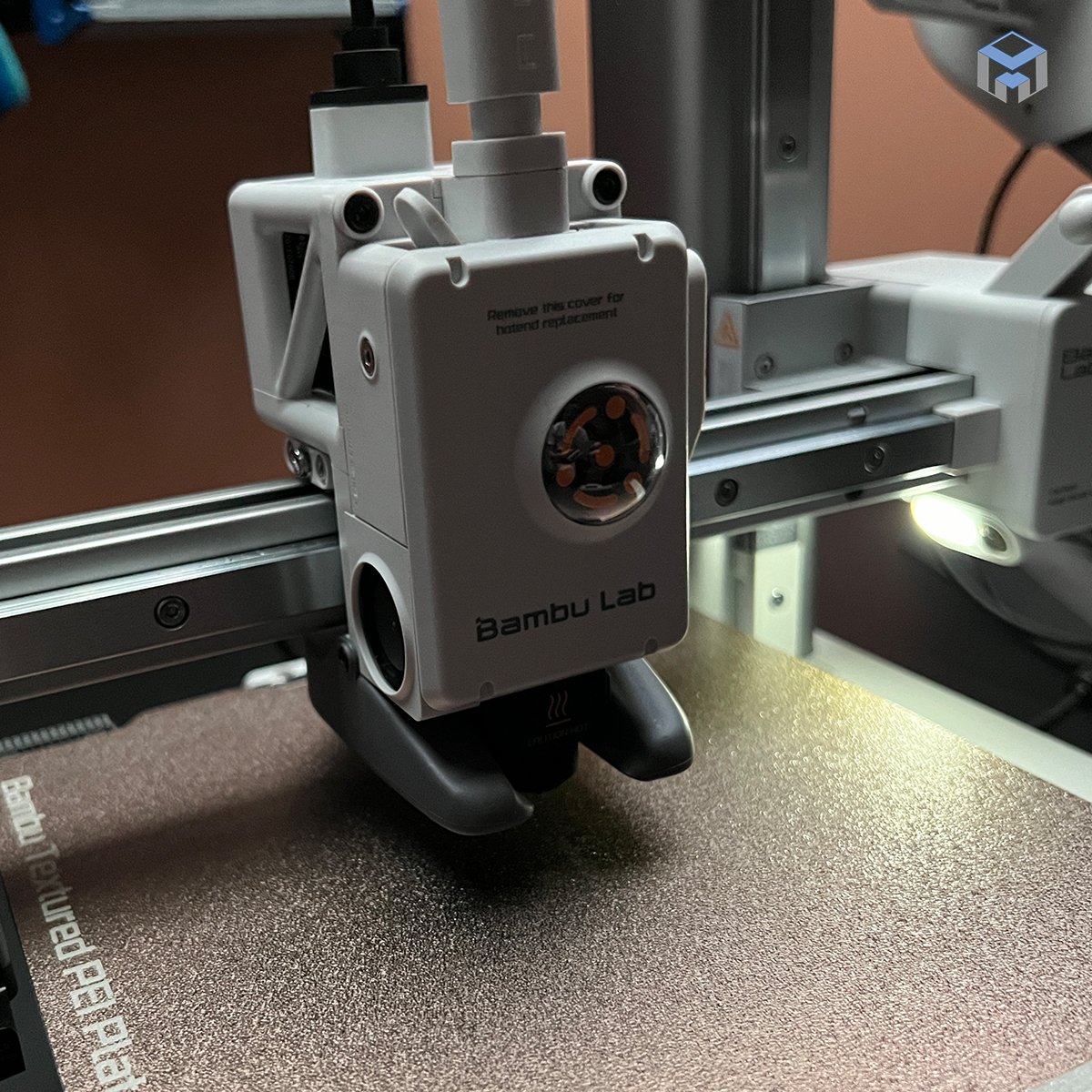

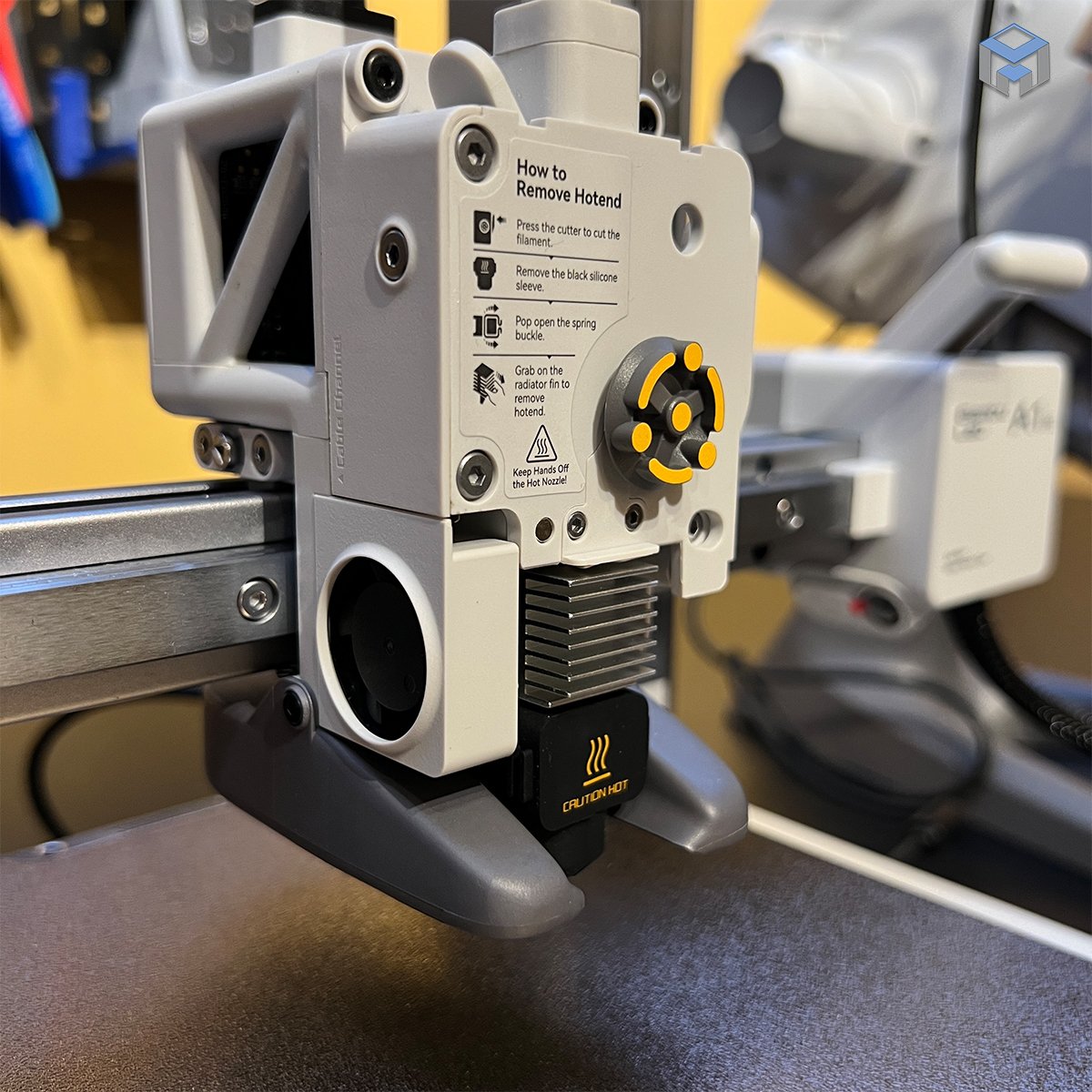

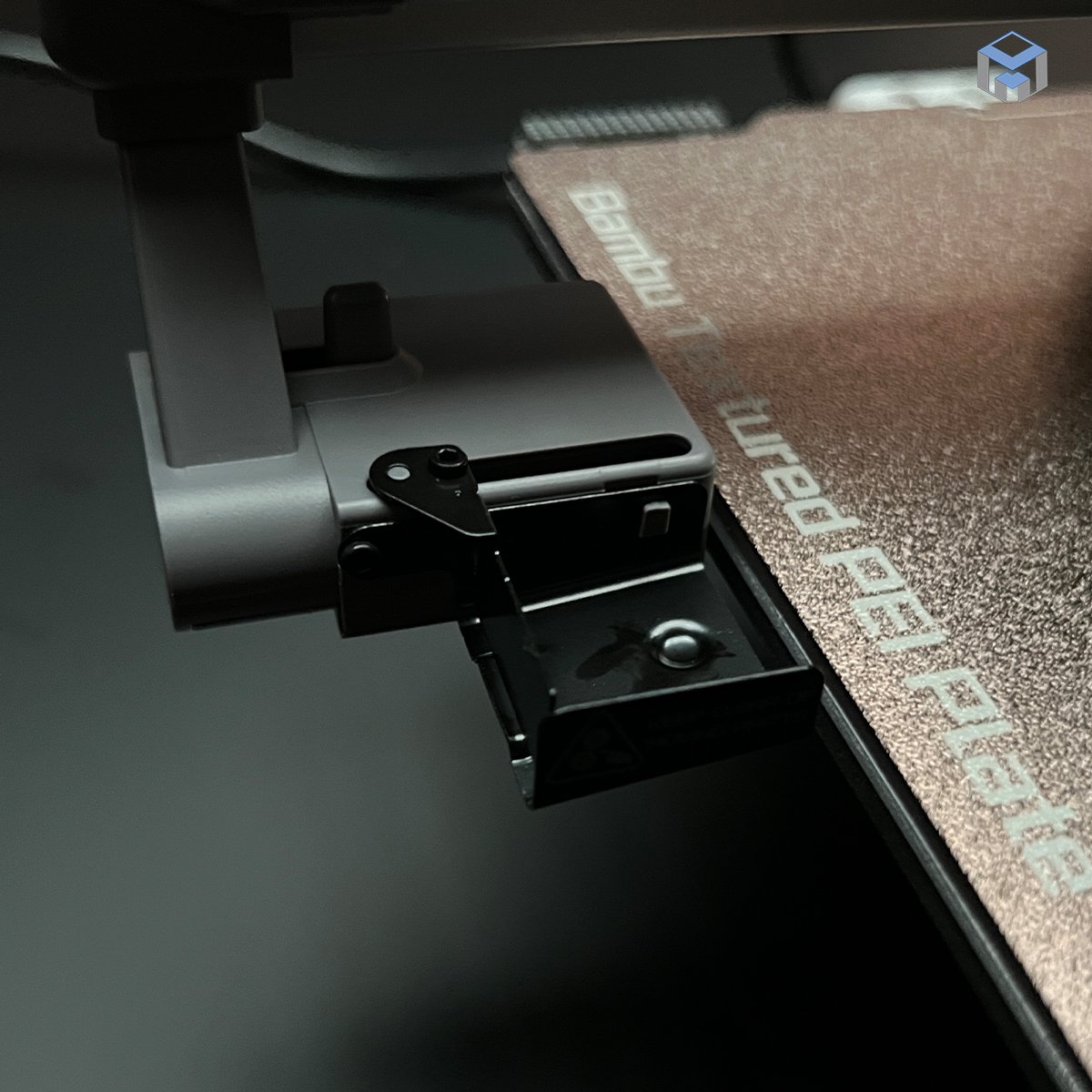

Advanced Hotend Assembly: The A1 Mini's hotend assembly stands out with its integrated design that combines the nozzle and heatsink, easily removable with a single clamp, ensuring a faster heating effect and simplified replacement. Accompanying the hotend are intuitive filament management systems; a filament hub and sensor for meticulous monitoring of filament feeding, cutting, and entanglement, alongside a cutter lever on the toolhead for efficient filament cutting. These features, along with the user-friendly maintenance design, not only streamline the printing process but also set a new standard in user convenience and multi-material printing capabilities.

Active Motor Noise Cancelling: The A1 Mini's Motor Noise Suppression feature minimizes common noises from mechanical vibrations, motor driving, fan operation, or extruder movement in 3D printing. By measuring undesirable motor characteristics in real-time during printing and applying necessary compensation, it generates reverse vibrations to counteract disruptive vibrations. Additionally, a Motor Noise Calibration option in the calibration menu allows users to recalibrate the motor noise, enhancing the overall printing experience.

Auto-Calibration: The A1 Mini stands out with its Full Auto Calibration capability, autonomously managing a spectrum of calibrations for every print job. It meticulously fine-tunes the Z-offset, bed-level, vibration resonance, belt tension, and nozzle pressure, ensuring a seamless printing experience every time. This automated precision not only elevates print quality but also simplifies the user's journey from design to print, making 3D printing more accessible and enjoyable.

Precision Flow Control: By employing a high-resolution, high-frequency eddy current sensor, it diligently measures the pressure in the nozzle during the printing process. With these precise readings, the built-in algorithm actively adjusts the flow rate, ensuring accurate extrusion and enhancing the overall print quality, showcasing a blend of innovation and precision in managing the intricacies of 3D printing.

Automated Nozzle Cleaning: The A1 Mini comes equipped with a heatbed nozzle wiper, meticulously designed to ensure a clean nozzle before each print job commences. Once a print task is initiated, the nozzle wiper automatically performs a two-stage cleaning process without any manual intervention. The first stage, coarse wiping, effectively removes residual waste from the hot nozzle. Following this, the fine wiping stage ensures a smooth and pristine nozzle surface, setting the stage for precise printing. The heatbed nozzle wiper is pre-installed on the A1 Mini, and although replacing it is a standard maintenance procedure, acquiring a replacement is straightforward from the official store.

Advanced Resonance Compensation: The A1 Mini's Advanced Resonance Compensation feature mitigates mechanical vibrations during printing for smoother outputs. Initially, a Vibration Analysis is conducted to pinpoint resonance modes. Based on this analysis, compensation parameters are determined and applied during the Dynamic Adjustment phase. This intelligent mechanism significantly enhances print precision and accuracy, delivering superior results.

Quick Swap Nozzle: This is a new feature in the Bambu Lab lineup, the ability to quickly and easily swap out a nozzle. You simply release 1 latch and the hotend can be removed and replaced with another. Nozzle swapping has never been easier.

User-Friendly Interface: The A1 Mini comes equipped with a user-friendly touchscreen interface, simplifying the navigation through settings and monitoring of the printing process.

Efficient Part-Cooling: If you want to print fast, you must cool equally as fast or else you risk losing quality on your prints. The A1 Mini uses a 5015 centrifugal fan with two opposing air outlets to make sure the extruded filament hardens before that hotend lays down another on top.

Real-Time Monitoring: Equipped with a built-in illumination system and a 1080p camera, the A1 Mini allows for crystal-clear monitoring of your print jobs from virtually anywhere. Whether you're utilizing the Bambu Handy App or Bambu Studio, staying updated on your print progress has never been easier. Plus, the option to create stunning time-lapses of your prints adds a captivating dimension to your 3D printing experience.

Software and Connectivity

The Bambu Lab A1 Mini aims to provide a seamless user experience not only in terms of hardware but also through its software and connectivity options. Here’s a closer look:

Software:

Bambu Lab has invested not only in creating superior hardware but also in developing intuitive software to enhance the user experience. Their software suite comprises the Bambu Studio Slicer and the Bambu Handy app, both tailored to simplify the 3D printing process while offering remote control and monitoring capabilities. With these software tools, Bambu Lab ensures users have a seamless interaction with their printers, emphasizing ease of use and efficient management of print jobs from anywhere.

The Bambu Studio Slicer is a robust tool designed for preparing your models for printing. It comes with pre-made profiles, eliminating the guesswork and allowing users to slice models efficiently, even if they are new to 3D printing. Beyond slicing, it serves as a control hub for your printers, enabling you to manage and monitor print jobs in real time. The intuitive interface and detailed monitoring features ensure you are always in control, making the slicing and printing process a breeze.

On the other hand, the Bambu Handy app is not just a remote control tool but a gateway to an extensive 3D model platform, MakerWorld. This platform is integrated within the app, allowing users to search, slice, and send models to the printer with just a single click. For newcomers to 3D printing, getting the slicer settings right is a steep learning curve, often leading to failed prints. However, the Bambu Handy app, with its one-click operation and connection to MakerWorld, significantly simplifies this process, ensuring even the newest users can start printing quality objects with ease.

Read our overview of Bambu Lab MakerWorld here

The slicing experience offered by Bambu Lab is unparalleled in its simplicity and enjoyment. The feature to search for models with included slicing settings and send them to the printer with a single click eliminates the steep learning curve associated with slicing in other printers. Regardless of one's knowledge or experience with 3D printing, anyone can quickly print a high-quality part. Bambu Lab has efficiently streamlined this process, making it an overall enjoyable experience.

Connectivity:

The Bambu Lab A1 Mini offers flexible connectivity options to suit different user preferences. You can opt to load your print files onto the included Micro SD card, providing a reliable and straightforward way to get your prints started. On the other hand, if you prefer a wireless setup, the A1 Mini has you covered. Through Wi-Fi connectivity, you can effortlessly send your print jobs, control, and monitor your printer using either the Bambu Handy app or the Bambu Studio Slicer. This dual-mode connectivity ensures a seamless printing experience, whether you prefer the traditional method of using a Micro SD card or the modern, wireless control through the dedicated Bambu Lab software applications.

Firmware Updates:

The provision for firmware updates ensures that your printer stays up-to-date with the latest features and improvements. Bambu Lab provides a simple process for updating the firmware, ensuring the A1 Mini continues to evolve and improve over time.

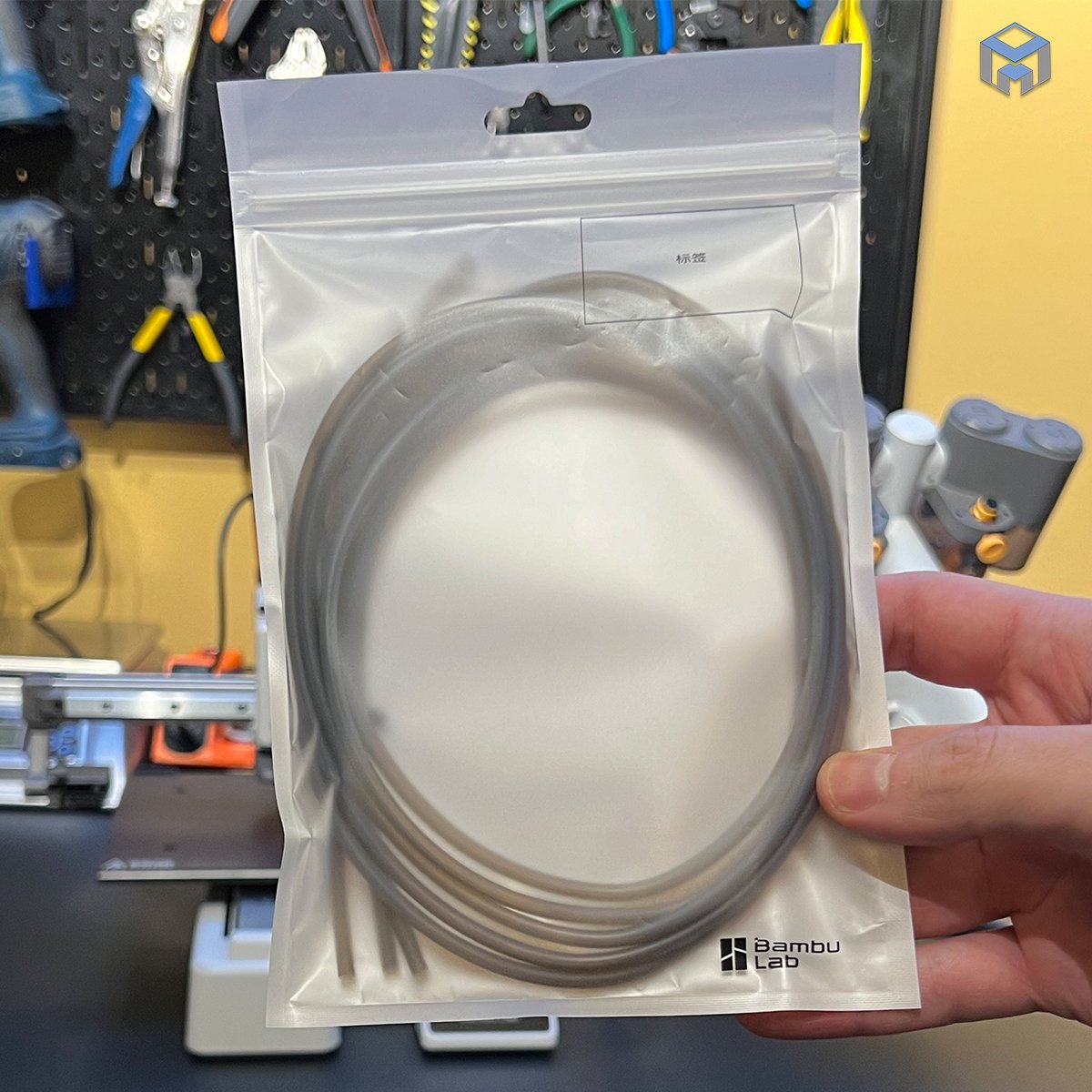

AMS Lite

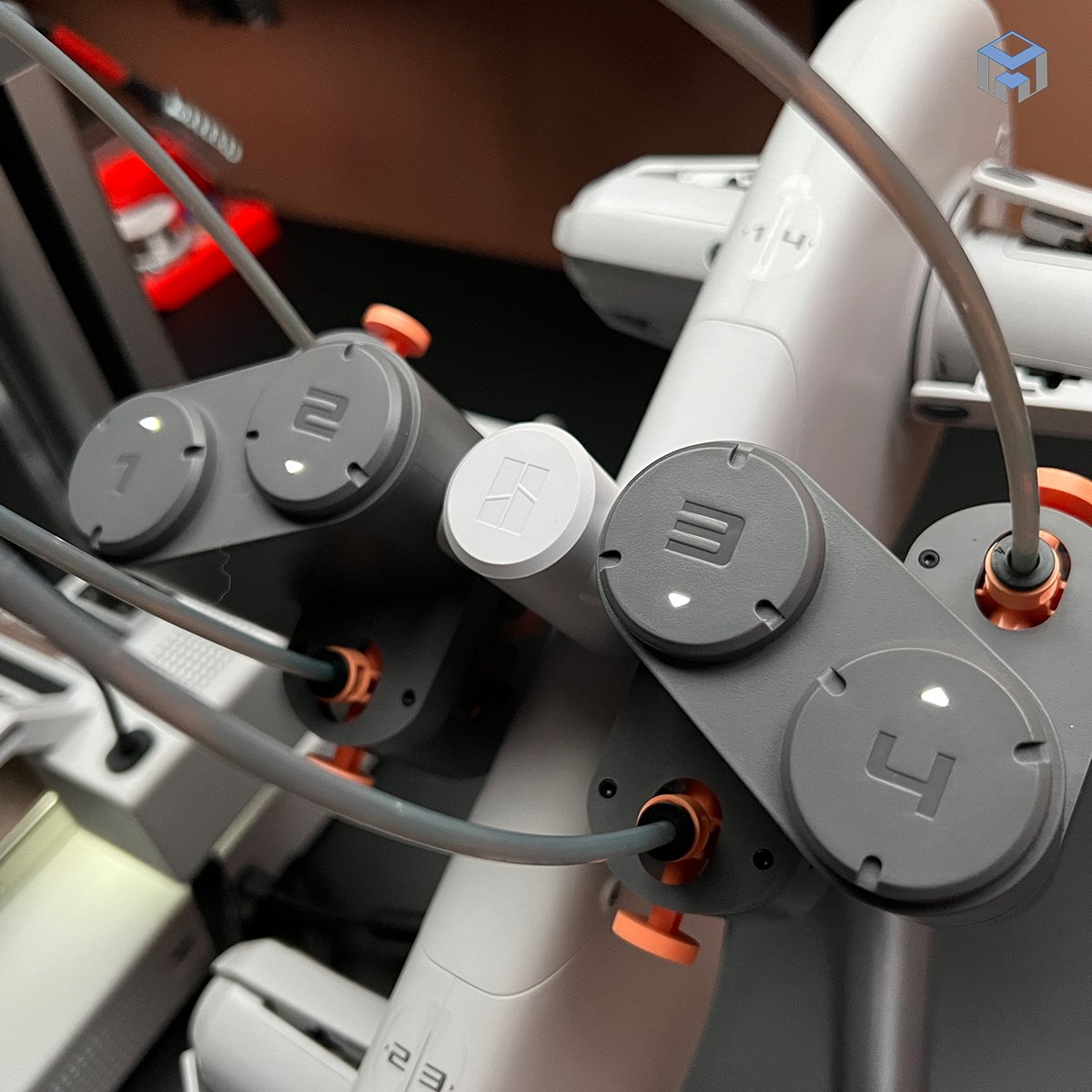

The AMS Lite is a cutting-edge filament feeding system ingeniously integrated into the A1 Mini by Bambu Lab, aiming to revolutionize filament management during the 3D printing process. Here are the distinctive features that distinguish this filament system:

Advanced Filament Monitoring

A clogged nozzle or a tangled spool can be a nightmare for any print job. The AMS Lite comes with a comprehensive filament monitoring system to nip such issues in the bud. Equipped with a filament tension sensor on the toolhead, a filament position sensor before the extruder, and a nozzle pressure sensor between the extruder and the nozzle, it's poised to detect and rectify potential issues such as filament tangling, breakage, and extruder skipping, ensuring that each print maintains its desired quality.

Material Detection

The AMS Lite boasts an RFID reading feature, simplifying material detection. Each slot in the AMS Lite has a corresponding RFID coil, which, upon placing the spool on the rotary holder and inserting the filament, reads its information. This feature can be activated on the slicer either for updates on insertion/startup or manually, allowing for a seamless transition between different material types.

AMS Filament Backup

Run out of filament mid-print? Worry not. The AMS Lite has a neat filament backup function that automatically switches to another spool with the same filament properties when the current filament runs out. This feature requires filaments with exactly the same properties and is a lifesaver during those long print jobs.

Multi-Material Printing

The AMS Lite is not just a one-trick pony; it accommodates multi-material printing with ease. When you send a multi-colour print task in the slicer, the model is automatically matched to the closest colour filament in the AMS slots, making multi-material printing a breeze.

Automatic Mapping

The automatic mapping feature takes the hassle out of multi-material print jobs by smartly matching the model to the closest color filament in the AMS slots. It’s all about making 3D printing as user-friendly as possible.

Odometer

With a built-in odometer in each feeder, the AMS Lite keeps a precise track of the length of the sent filament, ensuring accurate filament usage and aiding in troubleshooting whenever necessary.

Enhanced Printing Experience

The integration of AMS Lite significantly minimizes manual input, making 3D printing more accessible, especially for newcomers. It embodies Bambu Lab's mission of making 3D printing user-friendly and less error-prone. The AMS Lite is a stride towards a hassle-free and enjoyable printing experience, aligning perfectly with the innovative spirit of Bambu Lab's A1 Mini.

So far, my experience with the AMS Lite has been exceptional. I simply place the filament on the rotary spool holder, and while pressing the yellow button, feed the filament into the unit. Upon sensing the filament's loading, the AMS Lite allows me to select the filament type either from the touchscreen or through the app/slicer. That's all there is to it; the A1 Mini takes over from there, managing the filament loading and unloading to the nozzle seamlessly.

Maintenance and Support

Maintaining your A1 Mini is straightforward, thanks to its user-centric design. Here's a breakdown of what you can expect in terms of maintenance and support:

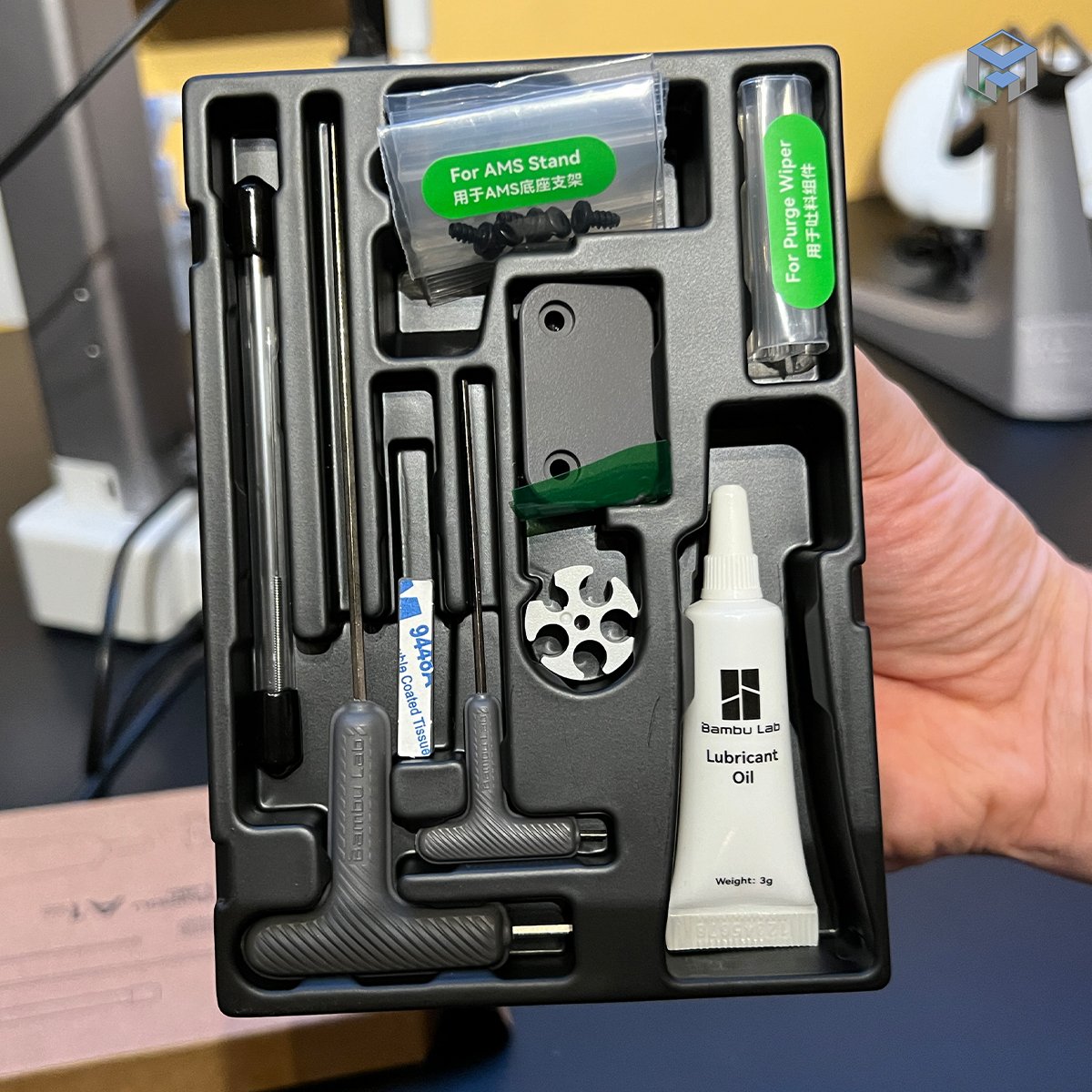

You’ll receive lubricant, replacement parts, and all the tools you’ll need to service your A1 Mini.

Maintenance

Routine maintenance tasks like lubricating the moving parts, replacing the nozzle, and replacing the nozzle cleaners are simplified. The accessible design of the A1 Mini makes it easy to reach necessary components, making maintenance less of a chore.

The toolkit that is included with the A1 Mini has all the tools and basic maintenance supplies that you’ll need to maintain your printer.

Support

Bambu Lab is dedicated to ensuring a seamless experience with the A1 Mini. They have established a comprehensive online knowledge base that addresses common troubleshooting issues, provides maintenance guides, and offers other helpful resources. In addition to the online resources, their customer support team is responsive and knowledgeable, ready to assist you with any challenges you may encounter.

Report any problems you encountered during the printing process.

A subtle yet standout feature is the ability to report problems whenever a print is stopped or upon its completion. This feedback mechanism reflects Bambu Lab's continuous drive for perfection. By allowing users to report issues, Bambu Lab not only enhances the user experience but also demonstrates a proactive approach to resolving problems and refining the printing process. This feature is a testament to Bambu Lab's dedication to product improvement and customer satisfaction, showing a forward-thinking approach that values user input for ongoing refinement.

Community

Technical hardware like the Bambu Lab A1 Mini greatly benefits from a strong community backing. Users inevitably face challenges or have queries, and a robust, engaged community is crucial for providing support. Through forums and social media groups, users can share experiences, find solutions to problems, and gain new insights. The collective knowledge within the community significantly eases troubleshooting, especially for those new to 3D printing.

Additionally, a vibrant community serves as a source of inspiration, enabling users to showcase their creations and share expertise. This exchange of ideas and experiences enhances the potential of the A1 Mini, making the user experience more rewarding. The camaraderie and collective problem-solving within the community elevate the user experience, embodying a supportive ecosystem around Bambu Lab’s offerings.

Pros and Cons

The Bambu Lab A1 Mini, like any other product, has its strengths and weaknesses. Here’s a balanced look at its pros and cons:

Pros:

Speed and Efficiency: The A1 Mini is designed for speed without compromising on print quality.

User-Friendly: The intuitive touchscreen interface and user-friendly software make it accessible to both beginners and seasoned makers.

Compact Design: Its small footprint makes it an ideal choice for space-constrained settings.

AMS Lite: The Automatic Material Sensor Lite adds a level of automation that simplifies material handling and gives you multi-colour printing ability.

Robust Support: With a comprehensive online knowledge base and responsive customer support, users can easily find help when needed.

Cons:

Build Volume: The compact design means a smaller build volume, which may limit the size of objects you can print.

Filament Restrictions: While it handles common filaments well, it might struggle with more exotic or specialty materials.

Proprietary Hardware/Software: You won’t be swapping in another company’s hotend or playing around in the config like a Klipper printer.

Who Is It For?

The Bambu Lab A1 Mini is tailored to a wide audience due to its user-centric design and robust features. Here's a breakdown of its appeal to different users:

Beginners:

The A1 Mini is engineered with the novice user in mind, catering to individuals who may not have prior knowledge or experience in 3D printing. It enables anyone to dive into the hobby of 3D printing without the need for extensive learning, calibration, or troubleshooting common issues that might arise.

As Dr. Ye Tao, CEO of Bambu Lab, mentioned in a recent interview, “A great portion of the newcomers gave up 3D printing I think within one or two months because they cannot repair clogged nozzle or the print quality is not up to the expectation or they just cannot you know figure out how to tune the printer to work properly I think that's a great loss for the community”. Through the A1 Mini, Bambu Lab endeavours to reduce these common barriers, making 3D printing a more accessible and enjoyable hobby for a broader audience.

Enthusiasts:

The A1 Mini offers a peek into the future of consumer 3D printing, with high-quality materials, auto-calibrating features, and high speeds, making it a desirable addition for any tech enthusiast who wants to be on the cutting edge.

Educators:

Its simplicity and safety features make the A1 Mini suitable for educational settings, providing a hands-on way for students to learn about 3D printing technology without a steep learning curve.

Professionals:

Professionals looking for a secondary printer or a portable option for quick prototyping will appreciate the A1 Mini's compact design and speedy performance. It’s a simple, reliable machine that provides amazing quality prints with very little downtime.

Small Spaces:

The A1 Mini's small size is perfect for tight spaces and easy transportation, addressing the needs of those constrained by space.

Pricing and Availability

The Bambu Lab A1 Mini is priced competitively, offering a blend of speed, compactness, and user-friendly features at a reasonable cost. It's an investment towards hassle-free and efficient 3D printing, accessible to a broad range of users.

Pricing:

Bambu Lab A1 Mini - $299 USD

Bambu Lab A1 Mini w/ AMS Lite - $459 USD

Availability:

Pre-orders start on Oct 16, 2023.

To check out the A1 Mini + AMS Lite from the Official Bambu Lab Store, click below:

Accessories:

Alongside the printer, Bambu Lab offers a range of accessories and consumables available for purchase. This includes additional filament, spare nozzles, and other maintenance tools that enhance the printing experience.

The Bambu Lab A1 Mini is not just a purchase, but an investment in a reliable 3D printing experience. With a reasonable pricing structure and availability through reputable channels, it's a worthy consideration for anyone looking to delve into or expand their 3D printing endeavours.

My Experience Summarized

Upon unboxing, setting up, and initiating a print job with the A1 Mini, the vision and mission of Bambu Lab became evidently clear – to usher new users into the 3D printing hobby by offering a seamless, enjoyable experience. Even the tactile feel of the printer during unboxing foreshadows the ensuing printing experience. Everything feels solid, and exudes a premium feel, yet embodies simplicity. I am hard-pressed to find another consumer 3D printer in the market that replicates the experience crafted by Bambu Lab. It leaves me wondering; had the A1 Mini been my initiation into 3D printing, what kind of user would I have morphed into? Perhaps less jaded, harbouring a more positive outlook on the hobby when sharing insights with others. Would my learning have spiked or levelled off if I had started with the A1 Mini? It's tough to say. I definitely spent many late nights on YouTube, figuring out calibration prints and slicer settings. While time-consuming, I gained valuable knowledge which is always a good thing. Although, I might regret the three nights wasted trying to set compile and flash Marlin firmware on my Ender 3—time I'll never get back.

Transitioning to the actual printing, the A1 Mini facilitated the first 3D printing experience that felt simple, a word I’ve used a lot throughout this review. The process is almost intuitive; power it on, slice a model in Bambu Studio, and the rest unfolds smoothly without a hitch—no fretting over filament loading, z-height adjustments, or bed levelling. Usually, 3D printing makes you focus more on the printer's needs, taking away from the actual thing you are printing. The A1 Mini changes this, letting you focus on what you're creating, not the machine creating it—a change I think Bambu Lab aimed for.

In online 3D printing forums like r/fixmyprint on Reddit, it's common to see new users struggling after setting up their printers. While many manufacturers provide basic setup instructions, they often leave users to figure out the crucial calibration process on their own. This part is key to fine-tuning the machine for better print quality. This hidden challenge in 3D printing could turn away many new users if they knew about it beforehand. Printers like a Creality or a Prusa can create great prints, but they require a good amount of knowledge and tend to print very slowly. It's disheartening to see a new user proudly share a print, mentioning it took over 48 hours to complete, as that's a lot of time that could be wasted if any small issue occurs during printing.

I used to suggest newbies start with an Ender 3, learn the ropes, and then upgrade. Now, I wouldn’t advise anyone to spend on such a low-performing machine. The A1 Mini offers a superior experience at a similar price.

Overall, the A1 Mini is an extremely impressive machine. I appreciate Bambu Lab's focus on simplicity and making 3D printing enjoyable. I believe the A1 will keep gaining followers and if Bambu Lab stays on this track, they could become the leading name in consumer 3D printing.

Speed Boat Benchy printed in under 13 minutes on the A1 Mini

Bonus: Speed Boat Benchy

Related Articles

Get an in-depth look at the Bambu Lab A1 Mini as we examine the key features of this 3D printer and discuss who it’s ideally suited for. Whether you're just starting in 3D printing or you're an experienced user, this article will provide essential insights to help you decide if the A1 Mini is the right choice for your printing needs.