E3D Revo High Flow - It's Here And It's Fast

There are a few big events and trade shows every year for additive manufacturing but one of the biggest just wrapped up in Chicago called Rapid + TCT. To quote their website: “Known worldwide as North America’s most important and largest additive manufacturing event, RAPID + TCT provides everything you need to know about the latest 3D-technologies, all under one roof.” If you’re wondering, the ‘TCT‘ stands for ‘Time-Compression Technologies’ which refers to the use of technologies such as 3D printing to accelerate and streamline the manufacturing process.

You can except a lot of big unveils and announcements at this event and this year we got one from E3D about an update to their Revo nozzle system. As there is only a limited amount of knowledge so far, we will cover we know and what we could expect in the future.

The Standard Revo

The Revo nozzle system was first released in October 2018 and since has become a very popular hotend option for many people. This is mostly due to its unique modular construction which allows users to swap nozzles very quickly. Just like the rest of the E3D lineup, the Revo is made out of top-grade materials and its unique design helps to prevent heat creep and ensure consistent, high-quality prints.

One drawback to the Revo has always been its flow rate, with a stock Revo getting around 11mm3/s. This is very low when compared to some of the other hotend offerings on the market. I’ve seen this be the crucial factor for users when deciding on a hotend for their new 3D printer builds.

High Flow Revo...it's here!

The new high flow Revo isn’t here to just rub shoulders with Rapido HF and the Mosquito hotend, it’s looking to blow right past them with its high volumetric flow rate and ease of use.

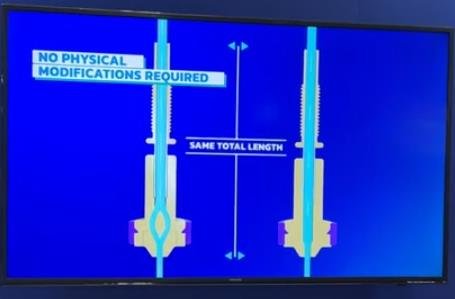

E3D claims the high flow Revo will be capable of a 40mm3/s flow rate which is a 70% increase over the standard Revo. Doing this while retaining the same size as a standard Revo.

The HF Revo is capable of doing this all thanks to its new high flow insert which resembles the inner workings of a Bondtech CHT nozzle. Instead of having a straight path from the heartbreak to the tip of the nozzle, the flow is broken up into a few channels which means there is more surface area for the filament to hit before it exits.

This design is probably one that all manufacturers should adopt but of course in the world of products and design, there will always be patents limiting what they are capable of.

In the video announcing its release, E3D spoke a little on patents and IP and mentioned a new partnership with Bondtech which hints at the potential for some new exciting products coming in the future.

They also spoke on how “collaboration is key to our industry’s success”. I doubt E3D would be saying this if they didn’t have a Bondtech roadblock in their way. As we saw with the patents held by Slice Engineering and the damage that they can do for the industry, patents can have a negative effect but can also have a positive one by forcing companies to be creative in their design and manufacturing. If there were no patents, we would see all of the major companies producing the same designs with very little risk taken.

Nozzle Sizes Available

E3D has a few more options available for the Revo with the full lineup being: 0.4mm / 0.6 / 0.8 / 1.0 / 1.2 / 1.4

Release Date

The high flow Revo will available from the E3D store and their global reseller network on May 17.

HevORT teams up with Mellow 3D to offer modular 3D printer kits, allowing for full customization and control over your printing setup.