The 3D Printing Titans of 2023: A Detailed Comparison of Creality K1, Bambu Lab X1, and Prusa XL

We’re living in a world where the power to create is at your fingertips, in the comfort of your home. That's the magic of 3D printing! And in 2023, there's never been a better time to get into it. There are so many cool 3D printers out there, but there are some that really stand out - we call these "flagship" printers. Just like a ship's flag stands out on the open seas, these printers stand out in the market because they're the very best that the companies can make. They're super fast, very precise, and packed with the newest features. In this article, we're going to compare three of these awesome machines - the Creality K1, Bambu Lab X1, and Prusa XL - and see what makes each of them special in the world of 3D printing.

The Evolution Of The Consumer 3D Printing Market

Over the past decade, the consumer 3D printing market has undergone a dramatic transformation. What was once a niche technology, often confined to the realms of industrial manufacturing and professional design, has now become an accessible tool for hobbyists, educators, and home users alike. The advent of affordable and user-friendly printers has democratized the technology, enabling more and more people to bring their creative ideas to life in three dimensions. In addition, the steady evolution of 3D printing materials, from basic plastics to an array of polymers, metals, and even ceramics, has expanded the range of applications for 3D printing, making it an increasingly versatile tool for creation and innovation.

3D printing was once strictly a hobby where gaining knowledge was considered “baptism by fire”. It involved a lot of tinkering, learning, and trial and error. With this new wave of technology, this is no longer the case. With companies aiming at producing products that deliver a ‘plug-and-print’ experience, this opens up the consumer 3D printing market to a whole new branch of customers. This lower cost of admission removes the barrier between a new user and producing amazing prints very quickly.

The Current State Of The Consumer 3D Printing Market

Advances in printing technology, such as increased print speed and resolution, automated calibration, and improved software, have resulted in printers that are not only more capable but also easier to use. The rise of flagship 3D printers, epitomizing the best of what their respective companies have to offer, has further pushed the boundaries of what is possible with home 3D printing. These high-performance machines showcase the cutting-edge of 3D printing technology, offering unparalleled precision, speed, and features that cater to both novices and seasoned makers.

As the printing technology changes and grows so does the needs of the users. No more late nights spent calibrating pressure advance for each new material, learning how to study input-shaping graphs, or setting up sophisticated auto-z macros. All of the focus is on how to get to the finish line as quickly as possible.

I think 3D printing has 2 main users, and always will. The first is the tinkerer, someone who enjoys the technology and is focused on the process of printing instead of just wanting a printed object. Second, is the user who needs a printed object, either an end-use part or a prototype. From what I can see, this second user base is the one that is growing and will continue to grow as long as the companies keep selling printers that are easy and fun to use.

As we dive deeper into the specifics of these three models, we will see how each has contributed to defining the current state of the consumer 3D printing market and how they continue to shape its future trajectory.

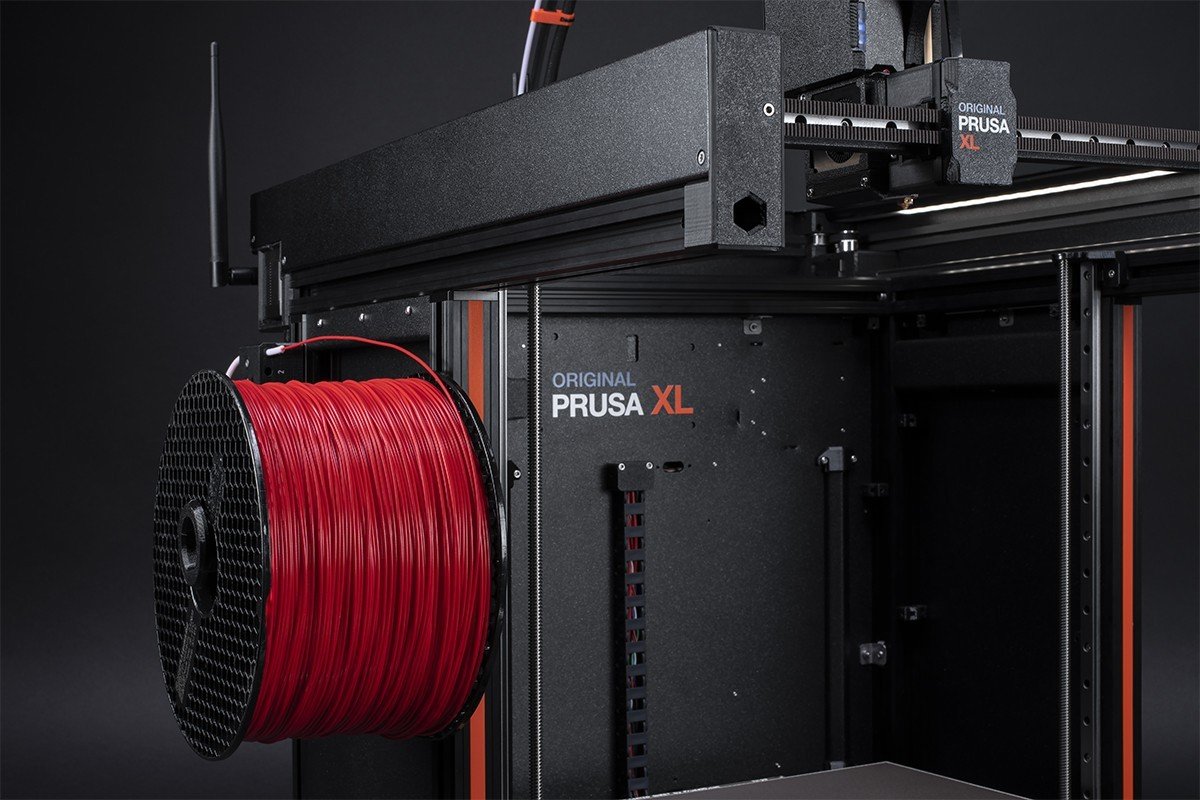

Prusa XL

| Feature | Details |

|---|---|

| Price (Assembled) | $2,499 |

| Price (Semi-Assembled) | $1,999 |

| Build Volume | 360x360x360 |

| Printer Dimensions | 800x800x900 |

| Filament Diameter | 1.75 |

| Lidar | No |

| AI Assistance | No |

| Max. Tool Head Speed | Unknown |

| Max. Tool Head Accel. | Unknown |

| Max. Hotend Flow | Unknown |

The world of 3D printing is a fast-paced and innovative space, and few brands have managed to leave as strong an imprint as Prusa. Their latest offering, the Prusa XL, is a testament to their commitment to pushing the boundaries of what consumer 3D printing technology can achieve.

The Prusa XL was first announced on Nov 18, 2021, and promised a new benchmark for consumer 3D printing. With features such as a new extruder, modular bed, and new 32-bit motherboard, the anticipation was palpable. But like any story worth telling, the journey of the Prusa XL from announcement to its final release wasn't without its trials and tribulations.

Following the announcement, Prusa had intended for a smooth production and release process. However, they encountered unexpected production issues that caused delays. Material shortages and supplier limitations caused them to either sit and wait or force a redesign of some of their key components. These setbacks not only pushed back the release date, but they also raised questions about whether the Prusa XL could live up to the hype.

Despite these challenges, Prusa was committed to quality and consumer satisfaction. They worked tirelessly to address the production issues, demonstrating their dedication to delivering a product that met their high standards.

As we move forward, the Prusa XL serves as a testament to Prusa's commitment to pushing the boundaries of 3D printing, even in the face of unexpected challenges. It's a reminder that in the world of technology, the path to innovation isn't always smooth, but the results can be nothing short of extraordinary.

Where’s The Speed?

The one main difference that sets the XL apart from the K1 and X1 is speed. While the others have speed as their main selling point, Prusa barely mentions this in their marketing.

To quote their website: “Just an upfront note: we are aiming for print quality, not looking to join the SpeedBoatRace. However, we are considering an unsupported, but official Klipper firmware for those looking to find the limits.”

Speed has definitely become an obsession for new users. The time-saving is definitely a huge benefit but I think it’s the ‘cool factor’ that is the big draw. Watching a printer produce a part at 400mm/s will never get old to watch.

While the XL may not win a race, it does offer a few features that the others haven’t even touched.

| Feature | Description |

|---|---|

| Nextruder | A new extruder with a built-in CPU and stepper driver, automated first layer calibration, load cell sensor for precise height calculation, planetary gearbox for improved filament control, hot-swappable nozzle and hotend for easy maintenance. |

| Segmented Heat Bed | Innovative design with 16 individually controllable segments for energy efficiency, reducing warping due to temperature changes, and heating only required segments for smaller prints. |

| Tool-changer | Up to five independent tool heads with a precise kinematic coupler mechanism for automatic tool alignment calibration and offsets configuration, eliminating manual calibration prints. |

| Mesh Bed Levelling | Load Cell-based fully automatic first layer calibration with no Live Z adjustment. |

| Electronics | 32-bit custom-made board with an expansion slot, single-cable communication with tool heads, network features, one-click printing. |

How Does It Compare?

As far as design goes, the XL is the only one to stand out from the pack. It features a coreXY build but with an open-front design which gives it a very unique and technical look.

When it comes to calibration and tuning, the XL has most of the features that you want to make the operation as stress-free as possible. It’s missing the AI technology though which is probably its biggest drawback.

Another key difference between the XL from the rest is the apparent lack of enclosure. When the XL was announced, they mentioned an enclosure that would be an add-on feature for the printer and not much has been said since. It’s not much of an enclosure, more of a draft shield that rises up from the bottom and still leaves the top of the printer completely exposed. We’ll have to wait and see if Prusa plans on an official add-on for this or if we’ll have to settle for 3rd party options.

The tool-changer presents both advantages and drawbacks. Its most significant advantage lies in the substantial reduction of waste during multi-material printing, a common issue when printing in multiple colours with a single extruder. By dedicating a toolhead to a single filament, the need for filament loads and unloads, which are the primary sources of waste, is eliminated. While this system is far more efficient in reducing waste compared to other multi-material printers, it still requires a transition tower for material changes. However, the transition tower produces significantly less waste, marking a notable improvement in waste reduction.

The cons are just price and power. We’ll have to wait and see how much power the XL consumes compared to the others but I’m guessing that when you have multiple toolheads all on standby mode, it will use considerably more power.

I’ll mention one last (optional) con: assembly. If you opt for the more affordable, semi-assembled version, be prepared for a fairly lengthy assembly process, especially when compared to other printers that are essentially ready to use straight out of the box.

Price

At $2,499 USD, this is well above the price of the K1 and X1. I think Prusa’s main target customer is someone who already owns a Prusa printer and has a high level of respect for the company. I think everyone else will just look at the price tag and focus on what they wouldn’t be getting instead of what they would be getting. This won’t be good for sales but I think the respect that their brand has will only continue to grow.

Competitive Analysis

Prusa's XL model strides into the higher-end spectrum of the consumer 3D printing market at $2,499, justifying its price with a suite of advanced features. It diverges from the speed-centric selling point of its competitors, emphasizing quality and reliability instead. With the XL, Prusa targets a niche segment of the market that values the brand's reputation for precision and customer satisfaction over cost savings. The XL appeals to seasoned 3D printing enthusiasts and professionals who require the printer's unique features, like the tool-changer and segmented heat bed, which offer distinct advantages for complex, multi-material prints.

Despite its premium price, the XL does face stiff competition from Creality's K1 and Bambu Lab's X1C, both of which boast lower prices and comparable print speeds. However, the XL carves out its own space by offering modularity and the brand's storied commitment to open-source development. This positions the XL as a long-term investment for users who prefer a robust community and extensive support for their high-end printing needs.

Bambu X1 Carbon

| Feature | Details |

|---|---|

| Price | $1,199 |

| Price (with AMS) | $1,449 |

| Build Volume | 256x256x256 |

| Printer Dimensions | 389x389x457 |

| Filament Diameter | 1.75 |

| Lidar | Yes |

| AI Assistance | Yes |

| Max. Tool Head Speed | 500 mm/s |

| Max. Tool Head Accel. | 20,000 mm/s² |

| Max. Hotend Flow | 32 mm³/s |

Bambu Lab was hard to miss in 2022 having made a significant splash with its X1 3D printer. The company seemingly came out of nowhere, with a product that has made waves in the consumer 3D printing market. As of January 2023, the Bambu Lab X1 has been reviewed as an exciting, feature-packed 3D printer that's far more than just aesthetically pleasing.

The X1 has not only been recognized for its impressive technical capabilities but also for its significant impact on the 3D printing industry. In fact, TIME named the Bambu Lab X1 among “The Best Inventions of 2022,” indicating its considerable influence in the space. This AI-powered 3D printer has quickly set a new standard in the industry, contributing to the conversion of the market into users who demand a more user-friendly, plug-and-print 3D printer.

The X1 started life as a campaign on Kickstarter, raising $7,033,789.10 USD from 5,560 backers, making it one of the most successful hardware campaigns of all time. The company has demonstrated not only ambition but also robust funding and a path to disrupt the 3D printing industry significantly. Its ability to transform the industry and pose a severe competitive threat over time has been acknowledged. The speed, quality, and user-friendly nature of the Bambu Lab X1 have set a new standard, suggesting a bright future for this innovative company in the 3D printing market.

All Those Features

Bambu Lab wrote on their Kickstarter “We hated 3D printing as much as we loved it” and it is this hatred that birthed all of the technology that’s present on the X1.

| Feature | Description |

|---|---|

| All Metal Hotend | 40W ceramic heater capable of 300℃, supports various filaments, including carbon/glass-filled polymers |

| Lidar Sensor | Lidar-guided bed leveling and first-layer inspection for precise printing |

| Failure Detection | AI-assisted camera to prevent print failures and filament jams |

| Multi-Color Printing | AMS (Automatic Material System) for up to 16 colors (additional cost) |

| Full Enclosure | 60℃ chamber temperature for successful printing of high-end technical filaments |

| Dual Automated Bed Leveling | Utilizes two sets of sensors for precise nozzle-to-bed distance measurement |

| High-End Build | CoreXY design with welded steel XY chassis, carbon X rail, and PC panels |

| Active Vibration Compensation | Incorporates input shaping for high-quality, sharp-looking prints |

| High Bandwidth Flow Control | Version of Pressure Advance that manages filament flow during speed changes |

| Wifi Connectivity | Remote control and monitoring of the printer from anywhere |

| Belt Tension Sensor | Small but impactful feature for improved print quality |

How Does It Compare?

It’s not hard to see that the X1 stands out from the rest in almost every way. It has a stylish, high-end design that is engineered to a very high standard.

It’s filled to the brim with tech and has created a user experience that will be hard to match. As they say “You don’t go backward in technology” so I can’t see anyone going back to a ‘normal’ printer after owning one of these.

The ability to print in multiple colours is one of their biggest selling features. I always thought that multi-colour printing for consumer machines would go the way of 3D TVs, having a little bit of time in the spotlight until it tucked itself away in the shadows unnoticed. It’s been a feature that was only available through limited options and all of them come with their list of troubles. Somehow, Bambu Lab has delivered it to the masses in a fool-proof way. Printing in 16 colors won’t be cheap but for the capability and the ease of use, you won’t find a better alternative on the market.

When it comes to speed, it matches the advertised rates of the K1. 500mm/s print speed with 20,000mm/s acceleration. It can print a 16 min benchy right out of the box.

Price

$1,199.00 USD will get you an X1 Carbon while $1,449.00 will get you an X1 Carbon Combo with includes their 4 filament AMS unit. This is an unbelievable price for a printer packed with this much tech.

Bambu Lab also has another offering for the money-conscious user, the P1P. It’s a stripped-down version of the X1, missing the enclosure and some of the AI tech features but still has all of the speed and access to multi-color printing. Priced at $699, it’s a great alternative to a ton of other printers on the market.

Competitive Analysis

The Bambu Lab X1C has garnered attention with a starting price of $1,199, which includes impressive features like AI assistance and Lidar-based auto-leveling, catering to a user base that looks for cutting-edge technology combined with ease of use. The X1C's balance of high speed, advanced features, and mid-range price point makes it a formidable player in the 3D printing arena. The inclusion of the AMS unit for multi-color printing at an additional $250 positions it as a versatile choice for both hobbyists and semi-professionals interested in producing intricate multi-color projects.

Bambu Lab's strategy seems to target both market ends, offering a high-tech printer that's reasonably priced. This positions the X1C as a bridge between cost-effectiveness and high performance, challenging both the lower-priced K1 and the higher-priced Prusa XL. With its contemporary design and an array of automated features, the X1C stands out as an attractive option for those wanting the latest in 3D printing without the Prusa XL's higher investment. It's a bold statement in a market that is increasingly leaning towards "smart" printers that simplify the printing process.

Creality K1

| Feature | K1 | K1 Max |

|---|---|---|

| Price | $599 | $999 |

| Build Volume | 220x220x250 mm | 300x300x300 mm |

| Printer Dimensions | 355x355x480 mm | 435x462x526 mm |

| Filament Diameter | 1.75 mm | 1.75 mm |

| Lidar | Optional | Yes |

| AI Assistance | Optional | Yes |

| Max. Tool Head Speed | 600 mm/s | 600 mm/s |

| Max. Tool Head Accel. | 20,000 mm/s² | 20,000 mm/s² |

| Max. Hotend Flow | 32 mm³/s | 32 mm³/s |

You're probably familiar with Creality's significant contributions to the 3D printing landscape. Their dedication to innovation has seen them dominate the market, with Q3 2022 witnessing their supremacy in unit shipments and revenue. Creality's commitment to creating accessible, low-cost 3D printers remains their defining characteristic and it’s what has made them so successful. How many 3D printing enthusiasts out there started out with an Ender 3? My guess would be the majority.

Taking center stage in Creality's bid to reclaim market dominance is their latest innovation, the K1 3D printer. This advanced model, in tandem with its larger counterpart, the K1 Max, is an embodiment of Creality's mission to redefine the standards of speed and quality in the consumer 3D printing market, recently disrupted by the rise of Bambu Lab. The K1's hallmark is its extraordinary speed, outperforming traditional printers by up to 12 times. Despite the complexities associated with achieving such speeds, even a moderated reduction to 400mm/s places the K1 well ahead of its competitors. With very aggressive pricing, the K1 and K1 Max represent Creality's strategic response to the evolving market dynamics, underlining their determination to reestablish their dominance in the consumer 3D printing sector.

| Feature | Description |

|---|---|

| New Hotend | New ceramic heater heats the hotend to 200℃ in 40 seconds with a max temp of 300℃. |

| Dual Hands-Free Auto Leveling | Automated bed leveling and bed mesh generation. |

| High-Speed Printing | Max. print speed of 600mm/s with a typical print speed of around 300mm/s. |

| Dual Cooling | Large fan on the printhead with an 18W auxiliary fan mounted inside the chamber. |

| Large Build Volume | 300x300x300 mm print area. |

| Lidar Sensor | Automated first layer + filament flow calibration. |

| AI Camera | Failure detection as well as real-time monitoring and timelapse recording. |

| Wifi Connectivity | Remote monitoring and control. |

| Air Purifier | Integrated into the chamber to filter out VOCs. |

| LED Lighting | Mounted inside the chamber. |

| Plug-and-Print | Assembled and calibrated before shipment. |

How does it compare?

Creality definitely had the X1 from Bambu Lab in their sights when they got to designing the K1. The die-cast aluminum construction gives it a high-end look and feel that consumers are growing to expect from a flagship printer. It also arrives fully assembled and calibrated from the factory.

Creality may claim a higher speed than the X1 but remember, the usable speed will be much lower and be on par with what the X1 is capable of. It has the same acceleration and max. flow rate as well.

The fully enclosed chamber with air purifier will make it easy to print your high-end filaments and the included hardened steel nozzle on the K1 Max will let you start printing with abrasive filaments right out of the box.

Just like the X1, Lidar, and AI technology take the tasks of calibration out of your hands. Auto-leveling, first layer calibration, input shaping, flow calibration, and a feature Creality calls “One Tap” that calibrates the entire printer for you.

The K1 has pretty much all of the features that you will find on the X1 except multi-color printing. You can of course buy a 3rd-party add-on like a Mosaic Palette 3 to take care of your multi-filament needs but I wouldn’t get your hopes up. Typically, hardware that is designed to work together usually will perform better than a 3rd party option.

Price Positioning of Creality K1

The Creality K1 series enters the market with an aggressive pricing strategy that's hard to ignore. At $599 for the base model and $999 for the K1 Max, these printers are clearly aimed at capturing a significant share of the consumer 3D printing market. Creality's pricing is not just about affordability; it's a strategic move to attract a broad user base, from newcomers to 3D printing enthusiasts looking for a machine that punches above its weight in terms of speed and features for its price range.

By undercutting the cost of printers like the Bambu Lab X1 and Prusa XL, which come in at $1,199 and $2,499 respectively, the K1 offers a compelling choice for those who prioritize high functionality at a lower cost. This competitive pricing positions the K1 as an attractive option for buyers who may be on the fence, potentially swaying them towards Creality's offering and away from higher-priced alternatives.

Competitive Analysis

When compared to its peers, the K1 stands out not just in cost but also in value. The standard model's feature set, which includes high-speed printing and hands-free auto levelling, is on par with more expensive models, while the K1 Max adds even more value with a larger build volume and advanced features like an AI camera and air purifier. These inclusions are reflective of Creality's strategy to disrupt the market by offering more for less, making it a disruptive force against the more established and premium-priced models from competitors.

Comparison Chart

| Feature | Prusa XL | Bambu Lab X1 | K1 Max |

|---|---|---|---|

| Price | $2,499 | $1,199 | $999 |

| Build Volume | 360x360x360 mm | 256x256x256 mm | 300x300x300 mm |

| Printer Dimensions | 800x800x900 mm | 389x389x457 mm | 435x462x526 mm |

| Filament Diameter | 1.75 mm | 1.75 mm | 1.75 mm |

| Lidar | No | Yes | Yes |

| First Layer Calibration | Yes | Yes | Yes |

| Filament Sensor | Yes | Yes | Yes |

| Automated Bed Leveling | Yes | Yes | Yes |

| Camera | No | Yes | Yes |

| Max. Tool Head Speed | Unknown | 500 mm/s | 600 mm/s |

| Max. Tool Head Accel. | Unknown | 20,000 mm/s² | 20,000 mm/s² |

| Max. Hotend Flow | Unknown | 32 mm³/s | 32 mm³/s |

| Max. Bed Temp | Unknown | 100℃ | 120℃ |

| Wifi Connectivity | Yes | Yes | Yes |

| Auxliary Cooling | No | Yes | Yes |

Final Thoughts

For as long as 3D printing has been available to consumers, it’s been in the hands of the real techies - folks with a mind for engineering and solving problems, always on the hunt for something new to learn. To use a 3D printer well, you needed this kind of mindset. If you've ever compiled your own Marlin firmware, you'll probably agree.

I used to tell newcomers to the hobby “3D printers are not appliances, they are machines with a lot of parts and variables. They are not plug-and-play.” This statement is no longer true when speaking about the X1 or K1.

These machines aren’t just lowering the bar for entry, they are trying to remove it. I think it is Bambu Lab that can be awarded this achievement.

As companies expand, they often become more risk-averse, opting for proven strategies that ensure stable growth and bolster their quarterly financial reports. Creality exemplifies this approach, regularly releasing new iterations of their existing printers. Despite the lack of novelty, these "sequels" to their products tend to perform well in the market, reinforcing the company's commitment to steady and consistent progress.

Bambu Lab's daring venture into the unknown has indeed yielded fruitful results, as evidenced by the significant online adoption of their product. This indicates a clear consumer preference for efficiency and speed, coupled with a desire for a stress-free user experience.

Prusa, conversely, has adopted a hybrid approach. Their foundation is anchored in the MK3S model, which has seen several iterations since its inception. Nonetheless, they have also chosen to explore innovation, albeit on a smaller scale, with the introduction of the XL model. Despite the XL's undeniable allure as a technological marvel, it tends to come off as somewhat dated when placed in direct comparison with the more recent X1 and K1 models.

We're in a thrilling phase for 3D printing, driven by an ‘evolve or fail' mindset brought on by Bambu Lab. However, the full impact of this shake-up will only become clear when Creality and Prusa's new models are in the hands of many customers.

Get an in-depth look at the QIDI Tech Q1 Pro in our detailed review. Find out how this desktop 3D printer delivers engineering-grade filament printing with unmatched precision, speed, and versatility.